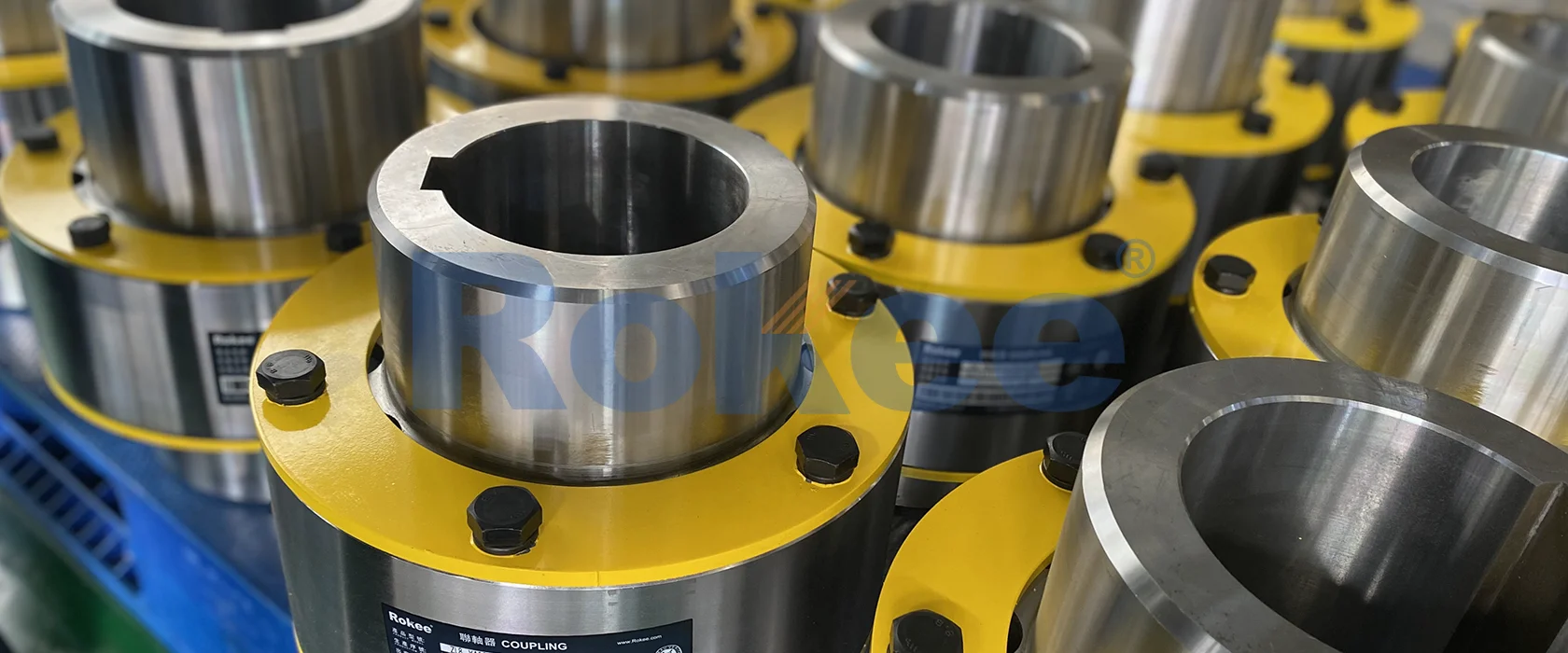

Rokee is a well-known high-quality supplier of Pin And Bush Couplings and technical services in China, customize pin and bush couplings according to user drawings, alternatively, if the user provides pin and bush couplings parameters, we can select the model and design drawings for you, support wholesale and export.

In the domain of industrial power transmission, couplings are indispensable components that establish a mechanical connection between two rotating shafts, enabling the seamless transfer of torque while accommodating inevitable misalignments and absorbing operational shocks. Among the various coupling types available, the pin and bush coupling has long been a staple in numerous industrial settings, valued for its simplicity in design, cost-effectiveness, and reliable performance in moderate to heavy-duty applications. Characterized by the use of cylindrical pins and bushings as the core torque-transmitting elements, this coupling type offers a practical solution for connecting shafts in machinery such as pumps, motors, compressors, and conveyors. Unlike high-precision metallic disc or membrane couplings, the pin and bush coupling prioritizes ease of manufacturing, installation, and maintenance, making it a preferred choice for general industrial use where extreme precision is not the primary requirement. This article comprehensively explores the construction details, working principles, material selection, performance characteristics, industrial applications, and maintenance considerations of pin and bush couplings, highlighting their enduring relevance in modern industrial power transmission systems.

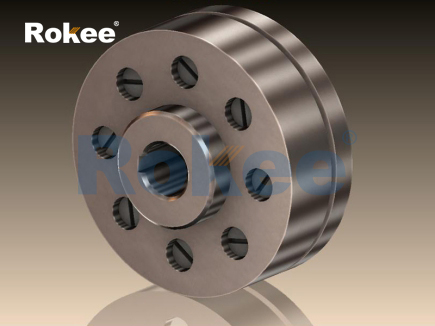

The pin and bush coupling features a straightforward yet robust construction, consisting of several key components that work in tandem to transmit torque and accommodate misalignments. The fundamental structure comprises two flanges, a set of cylindrical pins, bushings (also known as sleeves or rubber bushes), and fastening elements such as nuts and washers. Each flange is designed to be rigidly attached to the driving and driven shafts, respectively, using methods like keyway connections, set screws, or interference fits to ensure a secure, slip-free engagement. The flanges are typically circular in shape, with evenly spaced holes around their circumference to house the pins and bushings.

The pins are cylindrical metallic components that serve as the primary torque-transmitting medium. One end of each pin is firmly fixed to one of the flanges (usually the driving flange) using nuts and washers, while the other end extends outward and fits into the bushings mounted on the opposing flange (the driven flange). The number and size of the pins are determined by the torque requirements of the application; higher torque loads demand more pins or larger-diameter pins to distribute the load evenly and prevent premature failure. The bushings, which are often made of elastic materials such as rubber, neoprene, or polyurethane, are press-fitted or bonded into the holes of the driven flange. These bushings act as a flexible interface between the pins and the driven flange, playing a crucial role in absorbing misalignments and damping vibrations.

An optional but common component in pin and bush couplings is a protective cover (also called a guard or shroud). This cover is typically made of sheet metal or plastic and encloses the rotating pins and bushings to prevent accidental contact with personnel, protect the components from dust, debris, and moisture, and retain any lubricant used in the coupling. In some designs, the flanges may also be provided with recesses or grooves to facilitate the installation of the cover and ensure a secure fit. Additionally, the flanges themselves are usually fabricated from solid blocks of metal, with a thick, sturdy construction to withstand the mechanical stresses associated with torque transmission.

Variations in the basic design of pin and bush couplings exist to cater to specific application requirements. For example, the "pin and socket coupling" is a modified version where the bushings are replaced with sockets that have a spherical inner surface, allowing for greater angular misalignment. Another variation is the "flexible pin coupling," which uses bushings with a more pronounced elastic property to enhance vibration damping and misalignment compensation. These design modifications expand the versatility of pin and bush couplings, enabling them to adapt to a wider range of operating conditions.

The working principle of the pin and bush coupling is based on the transfer of torque from the driving shaft to the driven shaft through the interaction between the pins and bushings, while leveraging the flexibility of the bushings to accommodate misalignments and absorb shocks. When the driving shaft rotates, it imparts rotational motion to the driving flange, which in turn causes the pins attached to the flange to rotate. The rotating pins engage with the bushings mounted on the driven flange, exerting a tangential force on the bushings that drives the driven flange and, consequently, the driven shaft to rotate. This torque transmission process is efficient and direct, with minimal energy loss when the coupling is properly aligned and maintained.

A key aspect of the working principle is the role of the bushings in accommodating misalignments. Industrial machinery often experiences three types of misalignments between shafts: angular misalignment (where the shafts are inclined at an angle to each other), parallel misalignment (where the shafts are offset horizontally), and axial displacement (where the shafts move toward or away from each other). The elastic bushings in the pin and bush coupling deform slightly when subjected to these misalignments, allowing the pins to move relative to the driven flange without transmitting excessive stresses to the shafts or other components. For example, in the case of angular misalignment, the bushings on one side of the coupling compress slightly while those on the opposite side stretch, enabling the flanges to rotate at an angle relative to each other. Similarly, parallel misalignment is accommodated by the lateral deformation of the bushings, and axial displacement is absorbed by the axial compression or extension of the bushing material.

Another important function of the bushings is vibration damping. Rotating machinery generates torsional and lateral vibrations, which can cause noise, reduce operational efficiency, and lead to premature failure of components such as bearings and seals. The elastic bushings in the pin and bush coupling act as a buffer, absorbing and dissipating vibrational energy through their deformation. This damping effect helps to stabilize the operation of the machinery, reduce noise levels, and extend the service life of the entire power transmission system. Unlike rigid couplings, which transmit vibrations directly from one shaft to the other, the pin and bush coupling’s flexible bushings isolate the driving and driven shafts to a certain extent, minimizing the transfer of vibrations.

It is worth noting that the torque transmission capacity of the pin and bush coupling is limited by the strength of the pins and the wear resistance of the bushings. Over time, the bushings may wear due to the friction between the pins and the bushings during rotation and misalignment. This wear can lead to increased backlash (the clearance between the pins and bushings), which reduces the precision of torque transmission and may cause additional vibration. Regular maintenance, such as inspecting the bushings for wear and replacing them when necessary, is therefore essential to ensure the continued reliable operation of the coupling.

The performance and durability of a pin and bush coupling are heavily dependent on the selection of appropriate materials for its components. Each component (flanges, pins, bushings, and fasteners) has distinct functional requirements, and the materials chosen must be able to withstand the mechanical stresses, environmental conditions, and operational demands of the application. The following sections outline the common materials used for each component and the factors influencing their selection.

Flanges are typically fabricated from metallic materials that offer high strength, rigidity, and resistance to fatigue. The most commonly used materials for flanges include cast iron, carbon steel, and alloy steel. Cast iron is a popular choice for general-purpose applications due to its low cost, good castability, and adequate strength for moderate torque loads. It is widely used in couplings for pumps, fans, and small to medium-sized motors. Carbon steel, such as A36 or 45# steel, offers higher strength and durability than cast iron, making it suitable for heavy-duty applications with higher torque requirements, such as in steel mills, mining equipment, and large compressors. Alloy steel, which contains additional elements like chromium, molybdenum, and nickel, provides enhanced strength, toughness, and resistance to wear and corrosion, making it ideal for high-performance applications in harsh environments.

Pins are subjected to high shear and bending stresses during torque transmission, so they require materials with high tensile strength and shear strength. Common materials for pins include high-carbon steel, alloy steel, and stainless steel. High-carbon steel, such as 40C or 45C, is widely used due to its high strength and hardness after heat treatment. Alloy steel pins, such as those made from 40Cr or 35CrMo, offer superior toughness and fatigue resistance, making them suitable for applications with variable torque loads or high shock loads. Stainless steel pins, such as 304 or 316, are used in corrosive environments, such as in chemical processing plants or marine applications, where resistance to rust and chemical attack is essential.

Bushings are the flexible component of the coupling, and their material selection is critical for ensuring misalignment compensation, vibration damping, and wear resistance. The most commonly used materials for bushings are rubber, neoprene, polyurethane, and nylon. Rubber bushings are cost-effective and offer good flexibility and vibration damping, making them suitable for general-purpose applications. However, they have limited resistance to high temperatures and oil, so they are not ideal for high-temperature or oily environments. Neoprene bushings offer better resistance to oil, ozone, and weathering than rubber, making them suitable for outdoor applications or applications where the coupling is exposed to oil or other petroleum products. Polyurethane bushings provide higher wear resistance, better load-bearing capacity, and a wider temperature range than rubber and neoprene, making them suitable for heavy-duty applications with high torque loads and moderate temperatures. Nylon bushings are lightweight, have good self-lubricating properties, and are resistant to chemicals, making them suitable for applications where lubrication is difficult or where the coupling is exposed to corrosive chemicals.

Fasteners such as nuts and washers are typically made from carbon steel or stainless steel. Carbon steel fasteners are used for general-purpose applications, while stainless steel fasteners are used in corrosive environments to prevent rust and corrosion. Lock washers or spring washers are often used to prevent the nuts from loosening due to vibration during operation.

Pin and bush couplings exhibit a set of performance characteristics that make them well-suited for a wide range of industrial applications. One of the most notable characteristics is their simplicity and cost-effectiveness. The design of pin and bush couplings is straightforward, with fewer components than more complex coupling types such as metallic disc or gear couplings. This simplicity translates to lower manufacturing costs, making pin and bush couplings an economical choice for many industrial applications. Additionally, their simple design makes them easy to install and maintain, reducing downtime and operational costs.

Another key performance characteristic is their ability to accommodate moderate misalignments. While not as flexible as some elastic couplings, pin and bush couplings can effectively accommodate angular misalignments up to 1.5 degrees, parallel misalignments up to 0.5 millimeters, and small axial displacements. This flexibility is crucial in industrial settings where perfect shaft alignment is difficult to achieve or maintain, as it reduces the stress on shafts, bearings, and seals, extending the service life of the machinery. The elastic bushings also contribute to the coupling’s vibration damping capability, which helps to reduce noise and stabilize the operation of the rotating machinery.

Pin and bush couplings offer reliable torque transmission for moderate to heavy-duty applications. The torque capacity of these couplings ranges from a few hundred newton-meters to several thousand newton-meters, depending on the size of the flanges, the number and diameter of the pins, and the material of the components. This makes them suitable for a wide range of machinery, from small electric motors to large industrial compressors and conveyors. Additionally, the torque transmission is relatively efficient, with minimal energy loss when the coupling is in good condition.

However, pin and bush couplings also have some limitations. One of the main limitations is the wear of the bushings over time. The friction between the pins and bushings during rotation and misalignment causes the bushings to wear, leading to increased backlash. This wear is accelerated in high-speed applications, applications with frequent misalignments, or applications exposed to dust, debris, or moisture. Regular replacement of the bushings is therefore necessary to maintain the performance of the coupling. Another limitation is their limited high-temperature resistance. Most bush materials (such as rubber and neoprene) have a maximum operating temperature of around 80-100°C, making them unsuitable for high-temperature applications such as in furnaces or steam turbines. Additionally, pin and bush couplings are not suitable for applications requiring high precision torque transmission, such as in robotics or CNC machine tools, due to the potential for backlash.

Despite these limitations, the overall performance characteristics of pin and bush couplings make them a practical and cost-effective solution for many general industrial applications, where their simplicity, reliability, and ability to accommodate moderate misalignments outweigh their drawbacks.

Due to their simplicity, cost-effectiveness, and reliable performance, pin and bush couplings are widely used across a diverse range of industries and applications. Their ability to transmit moderate to heavy torques, accommodate moderate misalignments, and dampen vibrations makes them suitable for connecting shafts in various types of rotating machinery. The following sections highlight the key industrial sectors where pin and bush couplings are commonly employed.

The pump and compressor industry is one of the largest users of pin and bush couplings. Pumps and compressors are essential equipment in industries such as water treatment, oil and gas, chemical processing, and manufacturing. These machines often operate with moderate to high torque loads and may experience slight misalignments due to thermal expansion or vibration. Pin and bush couplings are ideal for these applications as they can transmit the required torque reliably, accommodate the inevitable misalignments, and dampen the vibrations generated by the pumps and compressors. Additionally, their simple design and easy maintenance make them a practical choice for pump and compressor manufacturers and operators.

The motor and drive system industry also extensively uses pin and bush couplings. Electric motors are used to power a wide range of machinery, from small fans and blowers to large industrial conveyors and mixers. Pin and bush couplings are commonly used to connect electric motors to the driven machinery, as they provide a secure and flexible connection. They are particularly suitable for induction motors, which may experience slight misalignments during operation. The vibration damping capability of the coupling also helps to reduce the noise generated by the motor and drive system, improving the working environment.

The mining and mineral processing industry uses pin and bush couplings in various types of equipment, such as crushers, conveyors, and separators. These applications involve heavy torque loads, frequent start-stop operations, and exposure to dust, debris, and harsh environmental conditions. Pin and bush couplings are able to withstand these harsh conditions, transmit the required torque, and accommodate the misalignments that may occur due to the heavy loads and rough terrain. The use of wear-resistant bush materials (such as polyurethane) in these applications helps to extend the service life of the coupling.

The agricultural industry also employs pin and bush couplings in farm machinery such as tractors, harvesters, and irrigation pumps. Agricultural machinery often operates in harsh and dusty environments, with frequent misalignments due to the uneven terrain. Pin and bush couplings are suitable for these applications as they are robust, can withstand the heavy torque loads, and are easy to maintain in field conditions. The vibration damping capability of the coupling also helps to reduce the fatigue of the machinery operators.

Other industrial applications of pin and bush couplings include fans and blowers, material handling equipment (such as conveyors and elevators), printing machinery, and textile machinery. In each of these applications, the coupling’s ability to transmit torque reliably, accommodate moderate misalignments, and dampen vibrations makes it a practical and cost-effective solution.

Proper maintenance is essential to ensure the reliable operation and long service life of pin and bush couplings. Regular maintenance helps to identify and address potential issues such as bushing wear, pin damage, and misalignment before they lead to coupling failure and machinery downtime. The following are key maintenance considerations for pin and bush couplings.

Regular inspection is the cornerstone of effective coupling maintenance. Inspections should be conducted at regular intervals (depending on the operating conditions and manufacturer’s recommendations) to check for signs of wear, damage, or misalignment. During inspection, the coupling cover should be removed to examine the pins and bushings. Signs of bushing wear include excessive clearance between the pins and bushings, cracking or tearing of the bushing material, and the presence of wear debris. Pins should be checked for bending, cracking, or corrosion. The flanges should be inspected for signs of distortion or damage, and the fasteners should be checked to ensure they are tight.

Bushing replacement is one of the most common maintenance tasks for pin and bush couplings. Due to the friction between the pins and bushings, the bushings will wear over time and need to be replaced. The frequency of bushing replacement depends on the operating conditions, such as the speed of rotation, the magnitude of misalignments, and the environmental conditions. When replacing bushings, it is important to use the correct type and size of bushings recommended by the coupling manufacturer. The old bushings should be removed carefully (using a press or other appropriate tools) to avoid damaging the flanges, and the new bushings should be press-fitted or bonded into place securely.

Lubrication is another important maintenance consideration for some pin and bush coupling designs. While many modern pin and bush couplings use self-lubricating bush materials (such as nylon or polyurethane), some designs require periodic lubrication of the pins and bushings to reduce friction and wear. If lubrication is required, the appropriate type of lubricant (such as grease or oil) should be used, and the lubrication should be applied at the recommended intervals. It is important not to over-lubricate, as excess lubricant can attract dust and debris, which can accelerate wear.

Shaft alignment should be checked and adjusted regularly to minimize stress on the coupling and other components. Misalignment between the driving and driven shafts can increase the wear of the bushings and pins, reduce the torque transmission efficiency, and cause additional vibration. Shaft alignment can be checked using tools such as a straightedge, feeler gauge, or laser alignment tool. If misalignment is detected, the machinery should be adjusted to correct the alignment.

Finally, the coupling cover should be inspected and maintained to ensure it is in good condition. The cover should be securely fastened to prevent dust, debris, or moisture from entering the coupling and causing damage. If the cover is damaged or missing, it should be replaced immediately to protect the coupling components and ensure the safety of personnel.

Pin and bush couplings have established themselves as a reliable, cost-effective, and versatile solution for power transmission in a wide range of industrial applications. Their simple yet robust construction, based on the interaction between metallic pins and elastic bushings, enables them to transmit moderate to heavy torques while accommodating moderate misalignments and damping vibrations. The selection of appropriate materials for the flanges, pins, and bushings ensures that the coupling can be tailored to meet the specific requirements of different operating environments and applications.

While pin and bush couplings have some limitations, such as the need for regular bushing replacement and limited high-temperature resistance, their advantages—including simplicity, cost-effectiveness, easy maintenance, and reliable performance—make them a preferred choice for general industrial use. They are widely employed in industries such as pump and compressor, motor and drive system, mining and mineral processing, and agriculture, playing a crucial role in ensuring the smooth and efficient operation of rotating machinery.

Proper maintenance, including regular inspection, bushing replacement, lubrication (if required), and shaft alignment, is essential to maximize the service life and performance of pin and bush couplings. With ongoing advancements in material technology, such as the development of more wear-resistant and high-temperature-resistant bushing materials, the capabilities of pin and bush couplings are continuously being enhanced, ensuring their continued relevance in modern industrial power transmission systems.

In summary, pin and bush couplings represent a practical and efficient solution for power transmission needs where extreme precision is not the primary requirement. Their enduring popularity across diverse industries is a testament to their reliability, simplicity, and cost-effectiveness, making them an indispensable component of the global industrial infrastructure.

« Pin And Bush Couplings » Post Date: 2024/4/25 , https://www.rokeecoupling.net/tags/pin-and-bush-couplings.html