Rokee is a well-known high-quality supplier of Universal Joints and technical services in China, customize universal joints according to user drawings, alternatively, if the user provides universal joints parameters, we can select the model and design drawings for you, support wholesale and export.

Universal joint is a mechanical device that can achieve power transmission between two non coaxial shafts. Its core function is to allow the two connected axes to deflect relative to each other within a certain angle range, while maintaining effective torque transmission.

Cross axis: a core component with four shaft necks distributed in a cross shape

Fork head components: usually have two, connecting the input shaft and output shaft respectively

Bearing component: supports cross axis rotation, reduces friction

Lubrication system: ensuring long-term reliability of operation

Compared with traditional rigid couplings, the prominent feature of universal joints is their ability to compensate for large shaft to shaft angular deviations (usually up to 15 ° -45 °), while allowing for a certain degree of axial and radial displacement, making them an ideal choice in complex transmission systems.

The working principle of universal joint is based on spatial geometric kinematics. When there is an angle between the input shaft and the output shaft, the rotation of the cross axis converts the uniform rotation of the input shaft into non-uniform rotation of the output shaft, and this speed fluctuation intensifies with the increase of the angle between the two axes.

Speed fluctuation: The output shaft speed varies periodically, and the fluctuation amplitude is proportional to the sine square of the deflection angle

Dual compensation: using two universal joints arranged in a specific way to eliminate speed fluctuations (such as a "Z" - shaped arrangement)

Load bearing capacity: The strength of the cross shaft and bearings determines the maximum transmitted torque

Efficiency loss: Typically, the transmission efficiency can reach 98% -99.5%, with lower efficiency as the angle increases

Modern universal joints have significantly improved the limitations of traditional structures through optimized design, such as using involute splines, special bearings, etc., resulting in a significant increase in maximum working angle and transmission efficiency.

With the development of industrial demand, universal joints have evolved into various structural forms, each with its own applicable scenarios and technical characteristics.

Cross axis universal joint

Basic type: Standard cross axis structure, low cost, most widely used

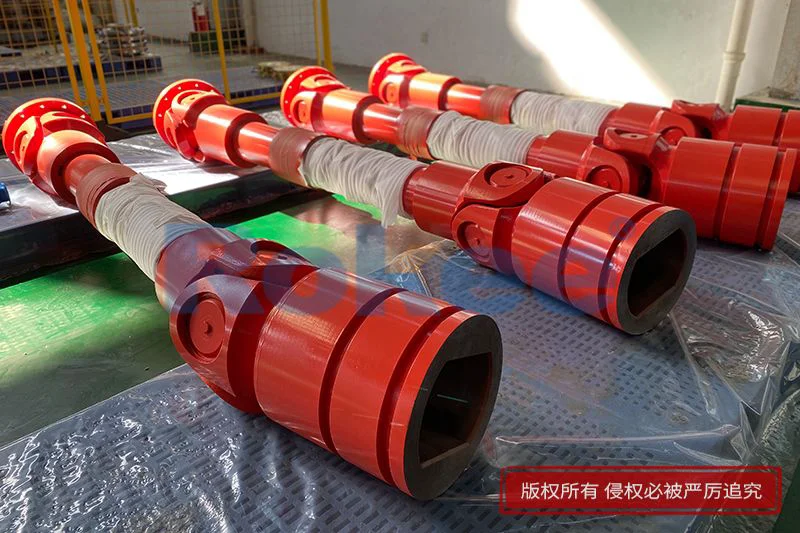

Heavy duty: reinforced design, used for heavy-duty applications such as metallurgy and mining

Miniature: Small scale design for precision instruments, such as camera gimbals

Ball cage constant velocity universal joint

Adopting a spherical cage and multiple steel ball structures

Realize true constant speed transmission without speed fluctuations

Widely used in front wheel drive systems for automobiles

Double universal joint

Two cross axis universal joints are connected through a spline shaft in the middle

Can compensate for larger offset and eliminate speed fluctuations

Used for long-distance transmission or situations requiring large deflection

Flexible universal joint

Replacing some metal components with elastic elements

Has vibration and noise reduction characteristics

Suitable for precision transmission and occasions that require vibration absorption

Automotive industry: transmission shaft, steering system, four-wheel drive system

Construction machinery: Transmission systems for excavators, loaders, cranes, and other equipment

Steel metallurgy: heavy equipment such as rolling mills and continuous casting machines

Shipbuilding industry: propulsion shaft system, servo system

Aerospace: Helicopter transmission system, aircraft control surface actuators

Energy equipment: wind turbine yaw system, oil drilling rig

Industrial robots: Joint transmission, precision positioning system

In the field of new energy, especially in wind turbines, universal joints play a key role in pitch and yaw systems, and their reliability and durability directly affect the overall performance of the machine.

Torque demand: Calculate maximum working torque and peak torque

Speed range: Consider the critical speed limit

Deviation angle: angle requirements under static and dynamic conditions

Environmental conditions: temperature, humidity, corrosiveness, etc

Space limitations: Installation size and weight constraints

Ensure that the alignment error of the two end axes is within the allowable range

Regularly check the lubrication condition and replenish or replace lubricating grease according to specifications

Monitor abnormal vibrations and noise to promptly detect bearing wear

Avoid overloading and impact loads to prevent cross axis fracture

Regularly check the wear of the spline fitting parts

Modern intelligent maintenance technology has begun to be applied to high-end universal joints, achieving predictive maintenance through vibration analysis, temperature monitoring, and other means, greatly improving equipment reliability and service life.

As a key component of mechanical transmission systems, the technological progress of universal joints directly affects the development level of the entire equipment manufacturing industry. In the future, with the continuous emergence of new materials and processes, universal joints will continue to demonstrate their unique value as "universal joints" in a wider range of fields.

« Universal Joints » Post Date: 2024/4/25 , https://www.rokeecoupling.net/tags/universal-joints.html