Rokee is a well-known high-quality supplier of Diaphram Couplings and technical services in China, customize diaphram couplings according to user drawings, alternatively, if the user provides diaphram couplings parameters, we can select the model and design drawings for you, support wholesale and export.

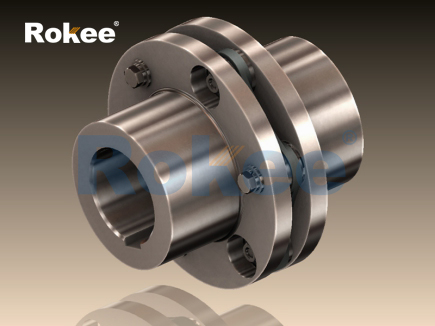

Diaphram Coupling is a high-performance flexible coupling that connects shafts through one or more specially designed metal diaphragms. Widely used in the industrial field, it gradually replaces traditional gear couplings and elastic couplings due to its excellent performance.

Core working principle: The Diaphram Coupling utilizes the elastic deformation of the metal diaphragm to compensate for radial, axial, and angular deviations between two connecting shafts. When the transmission system is running, the diaphragm absorbs vibration and impact through its own deformation, while maintaining extremely high torque transmission efficiency.

Metal membrane group: usually made of stainless steel or high-strength alloy steel, with a thickness between 0.2-1.5mm, arranged in a star or bundle shape

Shaft sleeve: a high-precision component that connects the drive shaft and the driven shaft

Middle section (some models): used to increase the length of the coupling or provide additional compensation capability

Fasteners: high-strength bolts and nuts to ensure connection reliability

No backlash design ensures high-precision transmission

No lubrication required, low maintenance cost

Compact structure saves installation space

The number and arrangement of membranes can be customized according to the working conditions

High end manufacturing field:

CNC machine tool spindle transmission

Precision measuring equipment

Semiconductor manufacturing equipment

Energy industry:

Gas turbine generator set

Wind turbine

Pump set transmission system

Transportation:

Ship propulsion system

High speed train transmission

Aerospace auxiliary power unit

Special environmental applications:

Key equipment of nuclear power plant

Deep sea operation machinery

High cleanliness environment

Torque demand: Calculate peak torque and sustained operating torque

Speed range: Consider critical speed and dynamic balance requirements

Deviation compensation: Evaluating the alignment error of the system

Environmental conditions: special requirements such as temperature, corrosiveness, explosion-proof, etc

Space limitations: Installation size and weight constraints

Determine basic transmission parameters

Calculate equivalent torque (considering operating condition factors)

Select coupling series and size

Verify whether the compensation capability meets the requirements

Check the adaptability to special environments

Clean the contact surface between the shaft end and the coupling

Using specialized tools to ensure precise alignment (recommended laser alignment instrument)

Step by step uniform tightening of bolts (usually using a cross sequence)

Perform initial operation check (low-speed no-load operation)

Regularly check the tightening status of bolts (recommended torque value recheck)

Monitor vibration and noise changes

Check for cracks or plastic deformation on the surface of the membrane

Record the trend of temperature changes during operation

As a key component of modern mechanical transmission systems, the technological evolution of Diaphram Couplings will continue to drive industrial equipment towards higher precision, efficiency, and intelligence. Correctly selecting and using Diaphram Couplings can significantly improve equipment performance and service life, and reduce overall operating costs.

« Diaphram Couplings » Post Date: 2024/4/25 , https://www.rokeecoupling.net/tags/diaphram-couplings.html