Rokee is a well-known high-quality supplier of Disc Membrane Couplings and technical services in China, customize disc membrane couplings according to user drawings, alternatively, if the user provides disc membrane couplings parameters, we can select the model and design drawings for you, support wholesale and export.

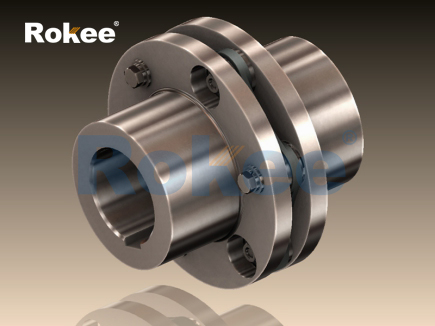

Disc Membrane Coupling is a high-performance flexible coupling that occupies an important position in modern mechanical transmission systems due to its unique structural design and excellent performance. This type of coupling connects shafts through one or more specially designed metal diaphragms, which can transmit torque and compensate for various forms of misalignment.

Compared with traditional gear couplings or rubber elastic couplings, Disc Membrane Couplings have significant advantages such as no backlash, maintenance free, high rigidity, and long service life.

Metal diaphragm assembly: A thin disk typically made of stainless steel (such as AISI 304, 316 or high-strength alloy steel), with a thickness generally between 0.2-1.5mm, depending on the magnitude of the transmitted torque. The membrane is designed with special curved openings or corrugated structures to provide necessary flexibility.

Wheel hub assembly: Two metal wheels connected to the drive shaft and the driven shaft respectively, usually made of high-quality carbon steel or alloy steel, with a hardened surface treatment.

Connecting bolts: High strength bolts firmly connect the diaphragm to the wheel hub, and the pre tightening force of the bolts is accurately calculated to ensure the reliability of the connection.

Intermediate section (optional): In some long-distance transmission applications, an intermediate coupling is added to increase compensation capability.

Torque transmission: The driving wheel hub transmits torque to the diaphragm through bolts, and the diaphragm then transmits torque to the driven wheel hub without relative sliding during the entire process, achieving precise transmission.

Deviation compensation: When there is radial, angular, or axial deviation between the two axes, the diaphragm undergoes elastic deformation to absorb these deviations. The special shape design of the membrane enables it to withstand large deformations while maintaining high fatigue life.

Vibration damping: Metal diaphragms have a certain filtering effect on high-frequency vibrations, and their rigidity can prevent the occurrence of low-frequency resonance.

High torque density: The ability to transmit torque per unit size is superior to most other types of couplings

Zero backlash transmission: ensuring the positioning accuracy of precision transmission systems

Wide temperature adaptability: stable performance within the range of -50 ° C to+300 ° C

Corrosion resistance: Stainless steel material can adapt to harsh environments

Lightweight design: small moment of inertia, especially suitable for high-speed applications

Transmission torque (T): rated torque and peak torque

Speed range (n): maximum operating speed and critical speed

Shaft diameter size: drive shaft and driven shaft diameter

Deviation situation: expected radial, angular, and axial deviations

Environmental conditions: temperature, humidity, corrosiveness, etc

Installation space restrictions

Single membrane type: simple structure, small compensation ability

Double membrane type: enhances compensation capability, most widely used

Multi diaphragm type: used for high torque and high-precision applications

Equipped with a middle section: specifically designed for long-distance transmission

Turbomachinery: compressors, turbines, expanders, etc

Pump equipment: chemical pumps, boiler feed pumps, seawater desalination pumps

Generator set: connection between gas turbine and diesel generator set

Steel metallurgy: transmission systems for rolling mills and straightening machines

Shipbuilding industry: propulsion shaft system, auxiliary engine connection

With the development of industrial equipment towards high efficiency, precision, and intelligence, Disc Membrane Couplings will continue to play a key role, and their technical performance and application scope will continue to expand. The correct selection and use of Disc Membrane Couplings are of great significance for improving the reliability and efficiency of mechanical transmission systems.

« Disc Membrane Couplings » Post Date: 2024/4/25 , https://www.rokeecoupling.net/tags/disc-membrane-couplings.html