Rokee is a well-known high-quality supplier of Elastic Pin Couplings and technical services in China, customize elastic pin couplings according to user drawings, alternatively, if the user provides elastic pin couplings parameters, we can select the model and design drawings for you, support wholesale and export.

Elastic pin coupling is a flexible connection device widely used in various mechanical transmission systems. It transmits torque between the driving shaft and the driven shaft through elastic elements (usually pins made of nylon or polyurethane), while allowing for a certain degree of axial, radial, and angular deviation. This type of coupling has become one of the most common coupling types in the industrial field due to its advantages of simple structure, easy installation, and low maintenance cost.

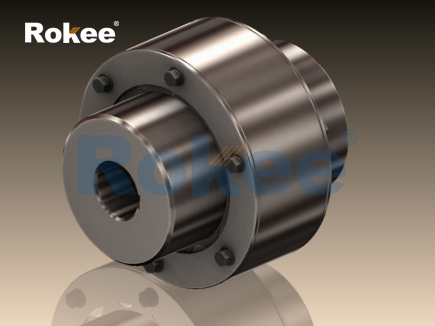

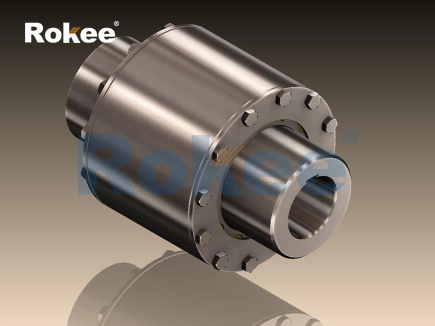

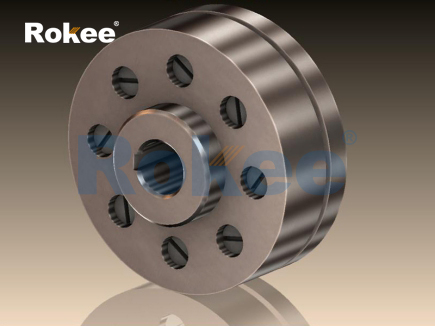

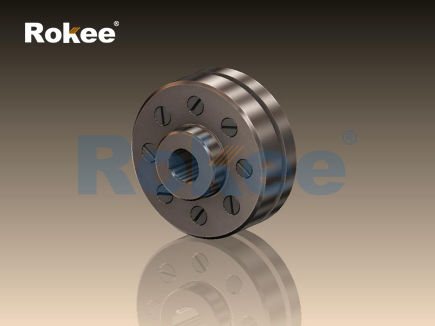

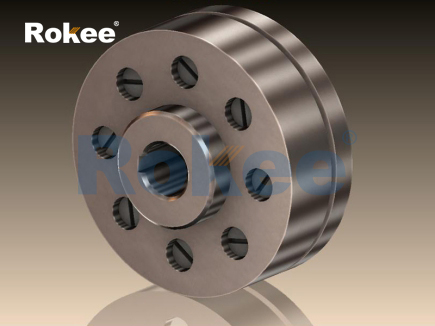

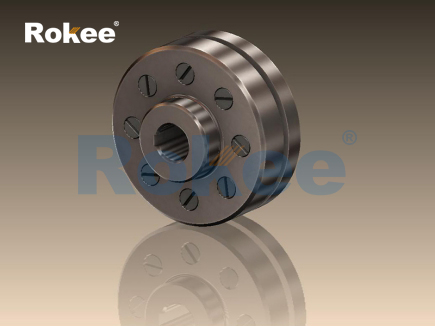

The core design concept of the elastic pin coupling lies in its unique elastic buffering mechanism. The basic structure consists of two half couplings (usually made of cast iron or steel) and a set of elastic column pins. The active half coupling is equipped with flanges and pin holes, while the passive half coupling is equipped with corresponding pin holes and rubber buffer rings. The column pins made of nylon or polyurethane pass through the pin holes of the two halves of the coupling, and absorb and buffer the vibration and impact during the transmission process through elastic deformation.

This structural design has three significant characteristics:

Elastic buffering capacity: The elastic properties of the pin material can effectively absorb vibrations and impacts, protecting the transmission system

Deviation compensation function: allows radial deviation of 0.5-1mm and angular deviation of 1-2 °

Overload protection: When the torque exceeds the rated value, the pin will first break, protecting more expensive equipment components

Elastic pin couplings demonstrate outstanding performance advantages in numerous industrial applications:

Vibration absorption capacity: Compared to rigid couplings, it can reduce vibration transmission by 30-50%, especially suitable for equipment such as motors and pumps that are prone to vibration.

Maintenance simplicity: Column pin replacement does not require moving equipment or disassembling the shaft system, greatly reducing maintenance time and costs. According to statistics, using elastic pin couplings can shorten maintenance time by more than 40%.

Economic efficiency: The procurement cost is only 1/3 to 1/2 of that of gear couplings, and the service life can reach 3-5 years (under normal working conditions).

The main application areas include:

Pump and fan drive system

Compressor and generator set

Conveyor machinery and material handling equipment

Small and medium power industrial machinery transmission

The correct selection of elastic pin coupling requires consideration of multiple technical parameters:

Torque capacity: Select based on 1.5-2 times the rated torque of the equipment, with commonly used specifications ranging from 10Nm to 5000Nm.

Speed limit: generally not exceeding 4000rpm, special design is required for high-speed applications.

Environmental adaptability: The standard model is suitable for environments ranging from -20 ℃ to+80 ℃, and special materials can be extended to -40 ℃ to+120 ℃.

Shaft hole form: Provides various options such as cylindrical holes, conical holes, and clamping types to adapt to different shaft end designs.

Proper installation and maintenance can significantly extend the service life of couplings:

Installation steps:

Clean the shaft end and coupling inner hole

Install using hot installation method (heated to 80-120 ℃) or hydraulic method

Ensure that the parallelism deviation of the two half couplings is ≤ 0.1mm

Uniformly tighten all connecting bolts

Maintenance suggestion:

Check the wear of the column pin every 3 months

When the elastic element shows obvious deformation or cracks, it should be replaced in a timely manner

Keep the coupling clean to avoid oil and dust accumulation

Regularly check the tightening status of bolts

Elastic pin couplings maintain an irreplaceable position in the field of mechanical transmission due to their excellent cost-effectiveness and reliable performance. With the advancement of Industry 4.0 and intelligent manufacturing, the new generation of intelligent and high-performance elastic pin couplings will provide more efficient and reliable connection solutions for equipment transmission systems. Proper selection, installation, and maintenance of elastic pin couplings can significantly improve equipment operating efficiency and reduce maintenance costs, making them an important component of modern industrial equipment management.

« Elastic Pin Couplings » Post Date: 2024/4/25 , https://www.rokeecoupling.net/tags/elastic-pin-couplings.html