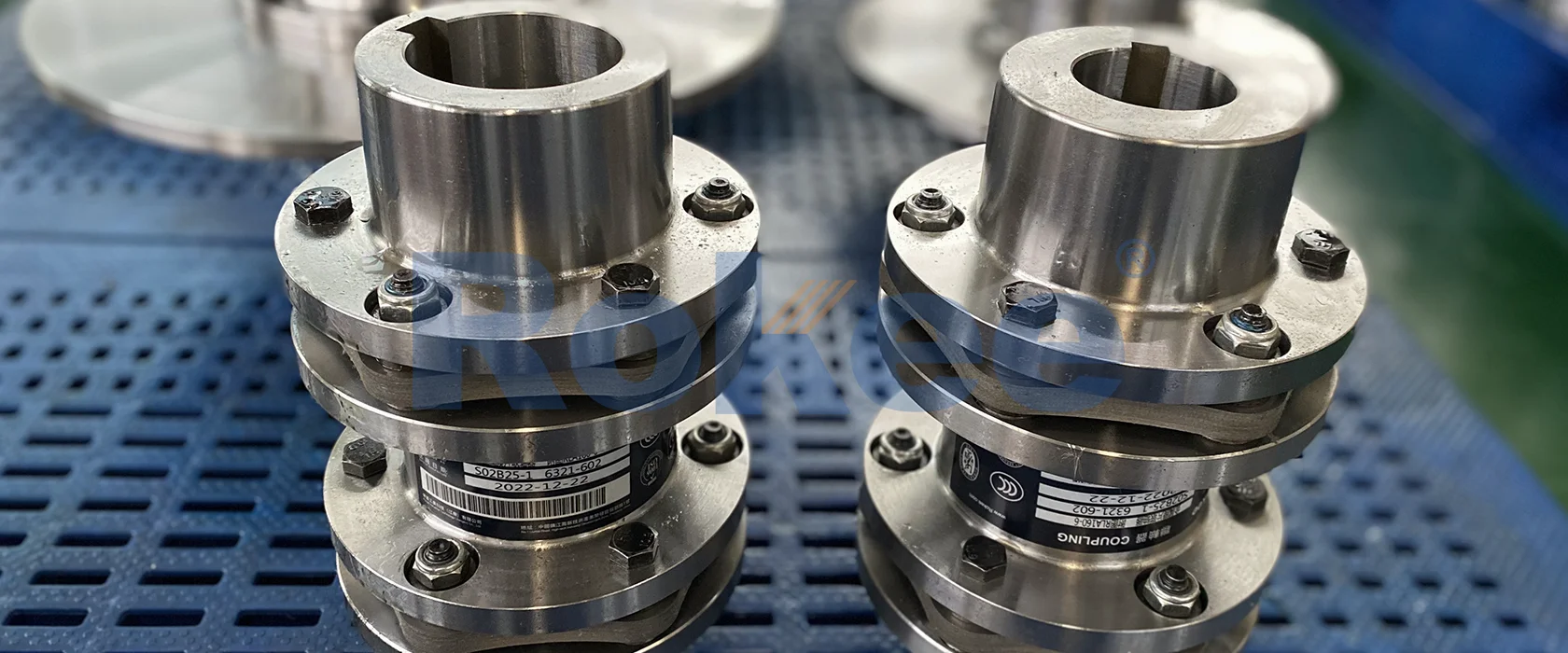

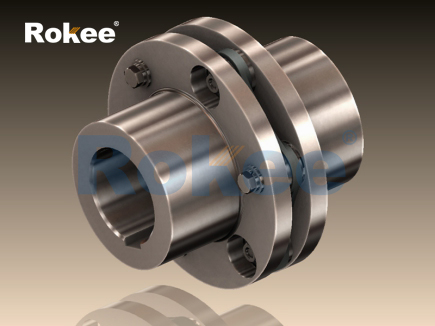

Rokee is a well-known high-quality supplier of Membrane Disc Couplings and technical services in China, customize membrane disc couplings according to user drawings, alternatively, if the user provides membrane disc couplings parameters, we can select the model and design drawings for you, support wholesale and export.

In the field of high-precision mechanical power transmission, the demand for couplings that can achieve efficient torque transfer while maintaining excellent alignment compensation and stability is increasingly prominent. Among various coupling technologies, the membrane disc coupling has become a core component in many high-end industrial applications due to its unique rigid-flexible composite structure, high transmission accuracy, and strong environmental adaptability. Unlike flexible couplings that rely on elastomeric elements for vibration damping, or rigid couplings that lack misalignment compensation capabilities, the membrane disc coupling realizes torque transmission and misalignment adjustment through the elastic deformation of metal membrane discs. This design not only ensures high torque transmission efficiency but also avoids the fatigue failure and environmental sensitivity problems of elastic components. This article comprehensively explores the membrane disc coupling, covering its structural composition, working principle, key performance advantages, typical application scenarios, scientific selection criteria, and practical maintenance methods. The purpose is to provide engineering and technical personnel with a systematic and in-depth understanding of this high-performance transmission component.

The structural design of the membrane disc coupling is sophisticated yet robust, mainly consisting of four core components: two shaft hubs, a membrane disc assembly, connecting bolts, and positioning sleeves. The shaft hubs are usually made of high-strength alloy steel (such as 45# steel, 40Cr) or stainless steel, which have excellent mechanical properties and wear resistance. The inner bore of the shaft hub is processed with high precision, and common connection methods with the driving and driven shafts include keyway fit, interference fit, and expansion sleeve connection. The keyway fit is suitable for general torque transmission scenarios, while the interference fit and expansion sleeve connection are more suitable for high-speed and high-precision applications, as they can reduce the concentricity error caused by the keyway and ensure more stable transmission. The membrane disc assembly is the core functional component of the coupling, which is composed of one or more metal membrane discs. The membrane discs are thin-walled circular parts processed by precision stamping or milling, and their materials are usually high-quality elastic alloys such as 304 stainless steel, 1Cr18Ni9Ti, or Inconel alloy. These materials have excellent elastic deformation ability, fatigue resistance, and corrosion resistance, which can ensure that the membrane discs do not undergo permanent deformation under repeated elastic deformation during long-term operation.

The structure of the membrane disc is carefully optimized. Common designs include solid disc type, slotted disc type, and multi-disc combination type. The solid disc type has a simple structure and high torque-bearing capacity, suitable for low-speed and heavy-load applications. The slotted disc type is processed with multiple evenly distributed slots on the disc surface, which can improve the flexibility of the membrane disc and enhance its misalignment compensation ability, making it suitable for high-speed and medium-load scenarios. The multi-disc combination type consists of multiple thin membrane discs stacked together, which can increase the total elastic deformation range of the membrane disc assembly while ensuring the torque transmission capacity, and is often used in applications requiring large misalignment compensation. The membrane disc assembly is connected to the shaft hubs through high-precision connecting bolts and positioning sleeves. The positioning sleeves ensure the coaxiality between the membrane discs and the shaft hubs, while the connecting bolts are usually made of high-strength alloy steel and undergo strict heat treatment to ensure the reliability of the connection. The bolt distribution is evenly arranged along the circumference of the membrane disc to ensure that the force on the membrane disc is uniform during torque transmission.

The working principle of the membrane disc coupling is based on the elastic deformation of the metal membrane disc. When the driving shaft rotates, it drives the driving shaft hub to rotate, and the torque is transmitted to the membrane disc assembly through the connecting bolts. Under the action of torque, the metal membrane discs generate elastic deformation. This deformation not only ensures the continuous transmission of torque but also realizes the compensation of three types of shaft misalignments: axial displacement, radial displacement, and angular displacement. Axial displacement refers to the relative movement of the two shafts along the axial direction, which is usually caused by thermal expansion and contraction of the shafts during operation or installation errors. The axial stretching or compression deformation of the membrane disc can absorb this displacement without generating additional axial thrust on the shafts and bearings. Radial displacement is the offset of the two shafts in the radial direction, which may be caused by shaft deflection under load or deformation of the equipment base. The radial bending deformation of the membrane disc can bridge the radial gap between the two shafts, ensuring stable torque transmission. Angular displacement is the angle formed between the axes of the two shafts, which is often caused by improper installation or inclination of the equipment. The membrane disc can generate asymmetric bending deformation to adapt to this angular misalignment, avoiding the generation of additional bending moments on the shafts and bearings.

It should be emphasized that the membrane disc coupling relies on the elastic deformation of the metal membrane disc to achieve misalignment compensation, and there is no relative sliding between the components during operation. This not only ensures high transmission accuracy but also avoids the wear problems caused by sliding friction. At the same time, the metal membrane disc has good vibration damping performance. Although it is not as good as elastomeric elements, it can still absorb part of the high-frequency vibration generated during the operation of the equipment, reducing the vibration transmission between the driving and driven shafts and improving the stability of the transmission system.

Compared with other types of couplings, the membrane disc coupling has numerous outstanding performance advantages, making it widely used in high-end industrial fields. Firstly, it has high transmission accuracy and efficiency. Due to the rigid connection between the membrane disc assembly and the shaft hubs, there is almost no backlash or relative sliding during torque transmission, and the transmission accuracy can reach 0.01-0.05 mm. The transmission efficiency is as high as 99.8% or more, which is particularly important for high-precision equipment such as CNC machine tools and precision robots. Secondly, it has excellent misalignment compensation capability. The membrane disc made of elastic alloy can effectively compensate for axial, radial, and angular misalignments. The maximum allowable radial displacement can reach 0.1-0.5 mm, the axial displacement can reach 1-5 mm, and the angular displacement can reach 0.5-3 degrees, depending on the model and size of the coupling. This reduces the requirements for precise alignment during installation and reduces the wear of shafts and bearings caused by misalignment. Thirdly, it has strong environmental adaptability. The metal membrane disc and shaft hubs made of stainless steel or high-temperature alloy have excellent corrosion resistance, high-temperature resistance, and low-temperature resistance. They can work normally in harsh environments such as high temperature (up to 300-500°C), low temperature (down to -50°C), humidity, and corrosion, and are not affected by factors such as oil, dust, and chemicals. This is incomparable to elastomeric flexible couplings that are sensitive to temperature and chemicals.

Fourthly, it has a compact structure and light weight. The membrane disc coupling adopts a modular design, with a small volume and light weight under the same torque transmission capacity. This is beneficial to reducing the overall weight and volume of the equipment, especially suitable for applications with limited installation space, such as aerospace engines, automotive transmissions, and precision machinery. Fifthly, it has a long service life and low maintenance costs. The metal membrane disc has excellent fatigue resistance, and its service life can reach 5-10 years under normal working conditions. Unlike elastomeric couplings that need to replace elastic elements regularly, the membrane disc coupling only needs regular inspection and does not require lubrication, which greatly reduces maintenance costs and downtime. Finally, it has high torque-bearing capacity. The membrane disc assembly composed of high-strength alloy can transmit large torques, and the maximum rated torque can reach several thousand N·m, which can meet the needs of heavy-duty industrial equipment such as large pumps, fans, and compressors.

Due to its excellent performance characteristics, the membrane disc coupling is widely used in various high-end and demanding industrial fields. One of the typical application fields is the aerospace industry. In aircraft engines, auxiliary power units (APUs), and flight control systems, the membrane disc coupling is used to connect various rotating components. The high-temperature resistance, high transmission accuracy, and light weight of the coupling are in line with the strict requirements of aerospace equipment. For example, in the connection between the aircraft engine turbine and the generator, the membrane disc coupling can work stably in a high-temperature environment above 300°C, ensuring efficient torque transmission and reliable power supply. Another important application field is the precision machinery industry, including CNC machine tools, machining centers, precision robots, and electronic component processing equipment. These equipment require high-precision motion transmission, and the membrane disc coupling's high transmission accuracy and small backlash can ensure the machining accuracy and motion control accuracy of the equipment. For example, in the connection between the servo motor and the ball screw of a CNC machine tool, the membrane disc coupling can transmit the torque of the servo motor to the ball screw without loss, ensuring the positioning accuracy of the machine tool's workbench.

The energy and power industry is also a major application field of membrane disc couplings. In thermal power plants, nuclear power plants, and wind power generation systems, the coupling is used to connect generators, steam turbines, water turbines, and wind turbine main shafts. The high torque-bearing capacity and reliable operation performance of the membrane disc coupling can ensure the stable operation of the power generation equipment. For example, in wind power generation systems, the membrane disc coupling can adapt to the slight misalignment caused by the deflection of the wind turbine main shaft under wind load, and transmit the torque generated by the wind turbine to the generator efficiently. At the same time, its corrosion resistance can adapt to the harsh outdoor environment. In the petrochemical industry, membrane disc couplings are used in large compressors, pumps, and reaction vessels. These equipment often work in high-temperature, high-pressure, and corrosive environments, and the membrane disc coupling's high-temperature resistance and corrosion resistance can ensure long-term reliable operation without being affected by the harsh environment.

Other notable application fields include the automotive industry (high-performance engines, hybrid vehicle drive systems), the marine industry (marine diesel engines, propeller shafts), and the medical equipment industry (precision medical imaging equipment, surgical robots). In each of these fields, the membrane disc coupling's unique performance advantages make it an indispensable core component of the transmission system.

Selecting the appropriate membrane disc coupling is crucial to ensuring the reliable operation of the transmission system, improving the performance of the equipment, and reducing maintenance costs. When selecting, the following key factors should be considered. Firstly, torque requirements. The rated torque of the selected coupling must be greater than or equal to the maximum working torque of the transmission system, including the starting torque of the motor and the impact torque during operation. A safety margin of 1.2-2.5 is usually recommended. For heavy-duty equipment with large impact loads (such as crushers, compressors), a higher safety margin (2.0-2.5) should be selected to avoid overloading the membrane disc and causing fatigue failure. Secondly, misalignment compensation requirements. It is necessary to accurately measure or calculate the actual misalignment (axial, radial, angular) of the two shafts in the system, and select a coupling whose maximum allowable misalignment is greater than the actual misalignment. If the actual misalignment exceeds the allowable range of the coupling, it will cause excessive stress on the membrane disc, accelerate fatigue damage, and reduce the service life of the coupling.

Thirdly, working speed. The maximum allowable speed of the membrane disc coupling must be greater than the working speed of the shafts. The working speed is related to the centrifugal force generated by the coupling during operation. Excessively high speed will generate large centrifugal force, which may cause deformation or damage to the membrane disc and shaft hubs. For high-speed applications (such as precision spindle systems, high-speed motors), it is necessary to select a coupling with a high maximum allowable speed, and conduct dynamic balance testing to ensure stable operation at high speed. Fourthly, working environment. According to the environmental conditions such as temperature, humidity, corrosion, and dust, select the appropriate material for the membrane disc and shaft hubs. For high-temperature environments, select high-temperature resistant alloys such as Inconel; for corrosive environments, select 316L stainless steel or titanium alloy; for normal temperature and dry environments, common alloy steel can be selected to reduce costs.

Fifthly, installation space and connection method. According to the installation space constraints of the equipment, select the appropriate coupling structure and size. For applications with limited axial space, select a compact single-disc membrane disc coupling; for applications with large radial space, a multi-disc combination type can be selected. At the same time, select the appropriate connection method (keyway fit, interference fit, expansion sleeve connection) according to the shaft structure and precision requirements of the equipment. Sixthly, transmission accuracy requirements. For high-precision equipment such as CNC machine tools and precision robots, select a membrane disc coupling with high transmission accuracy (backlash less than 0.02 mm) to ensure the motion control accuracy of the equipment. For general industrial equipment with low precision requirements, a coupling with ordinary transmission accuracy can be selected to reduce costs.

Proper maintenance of the membrane disc coupling is an important guarantee for its long-term stable operation and extended service life. The maintenance work mainly includes the following aspects. Firstly, regular inspection. It is recommended to inspect the coupling regularly. For high-speed and heavy-duty applications, the inspection cycle should be 1-3 months; for general applications, the inspection cycle can be 3-6 months. The key inspection contents include: checking whether the membrane disc has cracks, deformation, or fatigue wear; checking whether the connecting bolts are loose or damaged; checking the coaxiality of the shaft hubs and the wear of the positioning sleeves. If any defects are found, the relevant components should be replaced immediately to avoid sudden failure during operation.

Secondly, cleaning. Regularly clean the surface of the membrane disc coupling to remove dust, oil stains, and other impurities. Especially in dusty or corrosive environments, more frequent cleaning is required to prevent impurities from accelerating the wear and corrosion of the coupling components. When cleaning, use a neutral cleaning agent compatible with the coupling material to avoid corrosion of the membrane disc and shaft hubs. After cleaning, dry the coupling thoroughly to prevent moisture buildup. Thirdly, avoiding overload operation. Strictly control the operating load of the transmission system to ensure that the coupling works within the rated torque range. Overload operation will cause excessive deformation of the membrane disc, leading to fatigue damage and shortening its service life. It is recommended to install a torque monitoring device in the transmission system to monitor the operating torque in real time and alarm when overloading occurs.

Fourthly, proper installation and alignment. During installation, ensure that the coaxiality of the driving and driven shafts meets the requirements of the coupling. Use professional alignment tools (such as laser alignment instruments) for alignment to avoid excessive misalignment. Improper alignment is one of the main reasons for the premature failure of the membrane disc coupling. Fifthly, storage and handling. If the coupling is not installed immediately after purchase, it should be stored in a dry, ventilated, and clean environment to avoid moisture, corrosion, and dust pollution. The membrane disc is a precision component, and care should be taken during handling to avoid collision, bending, or scratching. When storing, the coupling should be placed horizontally to avoid deformation of the membrane disc due to long-term vertical placement.

With the continuous development of industrial technology, the performance requirements for membrane disc couplings are getting higher and higher. In the future, the development trend of membrane disc couplings will focus on the following aspects. Firstly, the development of new high-performance materials. The application of new materials such as carbon fiber composites and shape memory alloys in the manufacturing of membrane discs will further improve the performance of the coupling. For example, carbon fiber composites have the advantages of light weight, high strength, and corrosion resistance, which can reduce the weight of the coupling while improving the torque transmission capacity. Shape memory alloys can enable the membrane disc to automatically recover its original shape after deformation, improving fatigue life. Secondly, structural optimization and lightweight design. With the help of advanced design software such as finite element analysis and dynamic simulation, the structure of the membrane disc and shaft hubs will be further optimized to reduce weight and improve flexibility while ensuring strength. Additive manufacturing technology (3D printing) will also be widely used in the production of membrane disc couplings, enabling the manufacturing of complex-shaped membrane discs that are difficult to process by traditional methods, and improving the performance and customization level of the coupling.

Thirdly, the integration of intelligent technology. The integration of sensors (such as strain sensors, temperature sensors, vibration sensors) into the membrane disc coupling will realize real-time monitoring of its working state, such as monitoring the deformation of the membrane disc, operating temperature, and vibration amplitude. Through the analysis of monitoring data, potential faults can be predicted in advance, realizing predictive maintenance and improving the reliability and safety of the transmission system. Fourthly, the development of specialized products for extreme environments. With the expansion of application fields such as deep-sea exploration, space exploration, and nuclear energy, there will be a growing demand for membrane disc couplings that can work in extreme conditions such as ultra-high temperature, ultra-low temperature, ultra-high pressure, and strong radiation. Manufacturers will develop specialized membrane disc couplings through material innovation and structural design to meet these special requirements.

In conclusion, the membrane disc coupling is a high-performance mechanical transmission component with high transmission accuracy, excellent misalignment compensation capability, strong environmental adaptability, and long service life. It is widely used in high-end industrial fields such as aerospace, precision machinery, energy and power, and petrochemicals. The correct selection and proper maintenance of membrane disc couplings are crucial to ensuring the reliable operation of the transmission system and improving the performance of the equipment. In the future, with the development of new materials, structural optimization, and intelligent technology, membrane disc couplings will have broader application prospects and play a more important role in the field of high-precision mechanical transmission. For engineering and technical personnel, it is necessary to continuously deepen the understanding of membrane disc couplings, master their performance characteristics and application rules, and apply them more reasonably in practical engineering to promote the progress and development of industrial technology.

« Membrane Disc Couplings » Post Date: 2024/4/25 , https://www.rokeecoupling.net/tags/membrane-disc-couplings.html