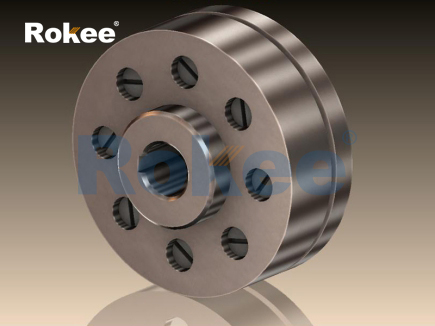

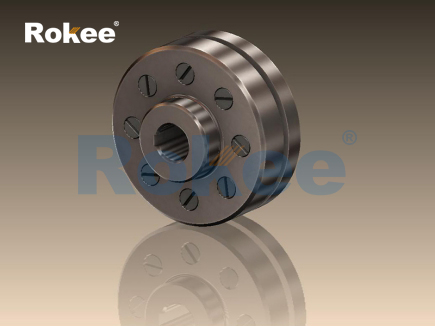

Rokee is a well-known high-quality supplier of Pin And Bushing Couplings and technical services in China, customize pin and bushing couplings according to user drawings, alternatively, if the user provides pin and bushing couplings parameters, we can select the model and design drawings for you, support wholesale and export.

In the realm of mechanical power transmission, couplings serve as critical components that connect two rotating shafts, enabling the transfer of torque while accommodating various forms of misalignment. Among the diverse range of coupling types available, the pin and bushing coupling stands out for its simplicity, cost-effectiveness, and reliability in numerous industrial applications. This article delves into the fundamental design characteristics, operational principles, material considerations, application scope, installation and maintenance practices, as well as emerging trends related to pin and bushing couplings, providing a comprehensive overview of this essential mechanical component.

A pin and bushing coupling, also commonly referred to as a pin-type coupling, is a rigid-flexible coupling that consists of two flanges—one attached to each shaft to be connected—along with a series of pins and bushings that facilitate the torque transfer between the flanges. Unlike fully rigid couplings, which offer no flexibility and require precise alignment, pin and bushing couplings incorporate a degree of flexibility through the bushing elements, allowing them to compensate for small to moderate amounts of angular, parallel, and axial misalignment between the connected shafts. This flexibility is crucial in real-world operating conditions, where shaft misalignment can occur due to factors such as thermal expansion, manufacturing tolerances, installation errors, or structural deflection under load.

The core advantage of pin and bushing couplings lies in their simplicity of design and construction. They have fewer components compared to more complex coupling types such as gear couplings or diaphragm couplings, which makes them easier to manufacture, install, and maintain. Additionally, their robust construction enables them to handle high torque loads, making them suitable for a wide range of industrial machinery and equipment. Despite their relative simplicity, pin and bushing couplings play a vital role in ensuring the efficient and reliable operation of power transmission systems across various sectors, from agriculture and mining to manufacturing and construction.

The basic structure of a pin and bushing coupling is composed of four main components: two flanges, pins, and bushings. Each component is designed to fulfill a specific function, and their combined design determines the coupling’s performance characteristics, including torque capacity, misalignment compensation, and service life.

Flanges

The flanges are the primary structural elements of the coupling, responsible for attaching the coupling to the respective shafts and providing the mounting points for the pins. Typically, each flange is a disk-shaped component with a central bore that matches the diameter of the shaft it is connected to. The bore may be equipped with keyways, splines, or set screws to ensure a secure, torque-transmitting connection between the flange and the shaft. In some cases, flanges may also feature tapped holes or through holes around their circumference, which are used to mount the pins.

The design of the flanges is critical to the coupling’s overall strength and torque-carrying capacity. The thickness of the flange, the number and size of the pins, and the material used all contribute to the flange’s ability to withstand the stresses generated during torque transmission. Flanges are usually designed to be symmetric, ensuring balanced rotation and minimizing vibration during operation. In high-speed applications, additional considerations such as dynamic balancing may be incorporated into the flange design to reduce noise and wear.

Pins

Pins are cylindrical components that serve as the torque-transmitting elements between the two flanges. They are inserted through the holes in one flange and secured in place, either by threading, cotter pins, or retaining rings. The other end of each pin fits into a bushing installed in the corresponding hole of the second flange. When torque is applied to one shaft, the pins transfer this torque to the bushings, which in turn transmit it to the second flange and shaft.

The number and diameter of the pins are key design parameters that determine the coupling’s torque capacity. Generally, a greater number of larger-diameter pins result in a higher torque-carrying capacity. However, the number of pins is also limited by the available space on the flange and the need to maintain balanced rotation. Pins are typically made from high-strength materials to withstand the shear and bending stresses encountered during operation.

Bushings

Bushings are cylindrical sleeves that are press-fitted or otherwise installed in the holes of one of the flanges. They act as a flexible interface between the pins and the flange, allowing for misalignment between the shafts. Bushings also serve to reduce friction and wear between the pins and the flange, extending the service life of the coupling.

The design and material of the bushing are critical to the coupling’s flexibility and wear resistance. Some bushings are made from elastic materials such as rubber or polyurethane, which provide high flexibility and damping capabilities, making them suitable for applications where vibration isolation is important. Other bushings may be made from metallic materials such as bronze or steel, which offer higher strength and durability but lower flexibility. In some cases, bushings may be lubricated to reduce friction, while self-lubricating bushings are also available for applications where regular lubrication is difficult or impractical.

The operational principle of a pin and bushing coupling is straightforward, yet effective. When one shaft rotates, it drives the attached flange, which in turn causes the pins mounted on that flange to rotate. The pins are inserted into the bushings installed in the second flange, so the rotation of the pins imparts a rotational force to the bushings. This force is then transmitted to the second flange, which drives the connected shaft, completing the torque transfer process.

The key to the coupling’s ability to accommodate misalignment lies in the interaction between the pins and the bushings. When the shafts are misaligned, the pins move within the bushings, allowing for relative motion between the two flanges. For example, in the case of angular misalignment (where the shafts are not colinear but intersect at a point), the pins pivot within the bushings, enabling the flanges to rotate at different angles while still transmitting torque. For parallel misalignment (where the shafts are parallel but offset), the pins slide within the bushings, accommodating the lateral displacement between the shafts. Axial misalignment (where the shafts move along their axial direction) is accommodated by the length of the pins and bushings, which allow for a small amount of axial movement.

It is important to note that pin and bushing couplings are designed to accommodate small to moderate amounts of misalignment. Excessive misalignment can lead to increased stress on the pins and bushings, resulting in premature wear, vibration, and ultimately, coupling failure. Therefore, proper alignment of the shafts during installation is essential to ensure optimal performance and longevity of the coupling.

The selection of materials for the various components of a pin and bushing coupling is critical to its performance, durability, and suitability for specific applications. The choice of material is influenced by factors such as the torque load, operating speed, environmental conditions (e.g., temperature, humidity, corrosive substances), and the level of misalignment expected. Below is a detailed overview of the common materials used for each component:

Flange Materials

Flanges are typically made from metallic materials due to their need to withstand high torque loads and provide structural rigidity. The most common materials used for flanges include:

Carbon Steel: Carbon steel is a popular choice for flanges due to its high strength, durability, and cost-effectiveness. It is suitable for a wide range of industrial applications with moderate torque loads and operating temperatures. Carbon steel flanges can be heat-treated to enhance their strength and hardness.

Alloy Steel: Alloy steel, which contains additional elements such as chromium, nickel, and molybdenum, offers higher strength, toughness, and resistance to wear and corrosion compared to carbon steel. It is used in applications with high torque loads, high operating speeds, or harsh environmental conditions.

Cast Iron: Cast iron is another common material for flanges, particularly in low to moderate torque applications. It is inexpensive, easy to cast, and has good damping properties, which help to reduce vibration. However, cast iron is brittle and may not be suitable for applications with high impact loads or excessive misalignment.

Pin Materials

Pins are subjected to shear and bending stresses during operation, so they require high strength and wear resistance. Common materials for pins include:

High-Strength Steel: High-strength carbon steel or alloy steel is the most common material for pins. These materials offer excellent shear strength and durability, making them suitable for high torque applications. Pins made from high-strength steel are often heat-treated to further enhance their mechanical properties.

Stainless Steel: Stainless steel is used for pins in applications where corrosion resistance is critical, such as in food processing, pharmaceutical, or marine environments. Stainless steel offers good strength and resistance to rust and other forms of corrosion, but it is more expensive than carbon steel.

Bushing Materials

Bushing materials are selected based on the desired level of flexibility, wear resistance, and operating conditions. Common bushing materials include:

Rubber: Rubber bushings are known for their high flexibility and excellent vibration damping capabilities. They are suitable for applications where vibration isolation is important, such as in automotive or agricultural machinery. However, rubber bushings have limited temperature resistance and may degrade over time when exposed to high temperatures or harsh chemicals.

Polyurethane: Polyurethane bushings offer a good balance of flexibility, strength, and wear resistance. They have higher temperature resistance than rubber and are more resistant to abrasion and chemicals. Polyurethane bushings are commonly used in industrial applications where moderate flexibility and durability are required.

Bronze: Bronze bushings are metallic bushings that offer high strength, durability, and wear resistance. They are often used in high-load, high-speed applications where flexibility is less critical. Bronze bushings require lubrication to reduce friction, but they can withstand higher temperatures than rubber or polyurethane bushings.

Self-Lubricating Materials: Self-lubricating bushings, such as those made from PTFE (polytetrafluoroethylene) or graphite-impregnated materials, are used in applications where regular lubrication is not feasible. These bushings have low friction coefficients and can operate without additional lubrication, reducing maintenance requirements.

Due to their simplicity, reliability, and cost-effectiveness, pin and bushing couplings find applications in a wide range of industries and machinery. Their ability to accommodate small to moderate misalignment and handle high torque loads makes them suitable for both light-duty and heavy-duty applications. Below are some of the key application areas:

Industrial Machinery

Pin and bushing couplings are widely used in various industrial machinery, including pumps, compressors, fans, and blowers. In these applications, the coupling connects the motor shaft to the impeller or rotor shaft, enabling the transfer of torque while accommodating minor misalignments that may occur due to thermal expansion or installation errors. For example, in centrifugal pumps, the coupling ensures that the torque from the electric motor is efficiently transmitted to the pump shaft, allowing the impeller to rotate and move fluid. The flexibility of the coupling also helps to reduce vibration, improving the overall efficiency and reliability of the pump.

Agricultural Machinery

Agricultural machinery, such as tractors, harvesters, and irrigation pumps, often operates in harsh and uneven terrain, leading to frequent shaft misalignment. Pin and bushing couplings are ideal for these applications due to their ability to accommodate misalignment and their robust construction. For example, in a tractor, the coupling may connect the engine to the transmission or to various auxiliary components such as PTO (Power Take-Off) shafts. The flexibility of the coupling helps to absorb the shocks and vibrations generated during operation, protecting the machinery from damage and ensuring smooth power transmission.

Construction Equipment

Construction equipment, such as excavators, loaders, and concrete mixers, requires couplings that can handle high torque loads and withstand harsh operating conditions. Pin and bushing couplings are commonly used in these applications to connect the engine to the hydraulic pump, transmission, or other rotating components. The robust design of the coupling ensures that it can withstand the heavy loads and vibrations associated with construction work, while the flexibility allows for misalignment caused by the movement of the equipment on uneven surfaces.

Manufacturing Equipment

In manufacturing facilities, pin and bushing couplings are used in a variety of equipment, including conveyors, mixers, and machine tools. Conveyors, for example, use couplings to connect the motor to the conveyor belt drive shaft, enabling the transfer of torque to move materials along the belt. The flexibility of the coupling helps to accommodate misalignments that may occur due to the long length of the conveyor or the weight of the materials being transported. In machine tools, such as lathes and milling machines, couplings are used to connect the motor to the spindle, ensuring precise torque transmission and reducing vibration, which is critical for achieving high-quality machining results.

Marine Applications

Pin and bushing couplings are also used in certain marine applications, such as small boats and ships, to connect the engine to the propeller shaft. In these applications, the coupling must be able to withstand the corrosive marine environment and accommodate misalignments caused by the movement of the vessel. Stainless steel or corrosion-resistant alloys are often used for the coupling components to ensure durability in saltwater environments.

Proper installation and regular maintenance are essential to ensure the optimal performance and longevity of pin and bushing couplings. Improper installation can lead to excessive misalignment, increased wear, and premature failure, while neglecting maintenance can result in reduced efficiency, vibration, and safety hazards. Below are the key steps and considerations for installation and maintenance:

Installation Process

Shaft Preparation: Before installing the coupling, the shafts should be cleaned to remove any dirt, rust, or debris. The shaft surfaces should be smooth to ensure a secure fit between the shaft and the flange. Any burrs or sharp edges on the shaft should be removed to prevent damage to the flange or the keyway.

Flange Mounting: The flanges are mounted on the respective shafts using keys, splines, or set screws. It is important to ensure that the flanges are mounted securely and that they are aligned as accurately as possible. The flange should be positioned such that the pins and bushings can be easily installed without excessive force.

Alignment: Proper alignment of the shafts is critical to the performance of the coupling. The shafts should be aligned both radially (parallel alignment) and axially (angular alignment). Alignment can be checked using tools such as a straightedge, feeler gauge, or laser alignment tool. Laser alignment tools are preferred for more precise alignment, especially in high-speed or high-torque applications. Any misalignment should be corrected before proceeding with the installation of the pins and bushings.

Pin and Bushing Installation: The bushings are first installed in the holes of one of the flanges, either by press-fitting or by using retaining rings. The pins are then inserted through the holes in the other flange and into the bushings. The pins should be secured in place using cotter pins, retaining rings, or threaded fasteners to prevent them from coming loose during operation.

Final Check: After installation, a final check should be performed to ensure that all components are properly installed and secured. The coupling should be rotated by hand to check for any binding or excessive resistance. If any issues are detected, they should be corrected before the machinery is put into operation.

Maintenance Practices

Regular Inspection: Pin and bushing couplings should be inspected regularly to check for signs of wear, damage, or misalignment. Inspections should include checking the pins and bushings for wear, cracks, or deformation; checking the flanges for signs of stress or damage; and checking the fasteners to ensure they are secure. Inspections should be performed at regular intervals, depending on the operating conditions and the manufacturer’s recommendations.

Lubrication: If the coupling uses lubricated bushings, regular lubrication is essential to reduce friction and wear. The type of lubricant used should be compatible with the bushing material and the operating conditions. Lubrication intervals should be followed strictly, and the lubricant should be changed periodically to ensure optimal performance. Self-lubricating bushings should be inspected to ensure that the lubricating material is not depleted.

Alignment Check: Over time, shaft alignment can change due to thermal expansion, structural deflection, or wear of the machinery. Therefore, it is important to check the alignment of the shafts regularly and correct any misalignment that is detected. This will help to prevent excessive stress on the coupling components and extend the service life of the coupling.

Component Replacement: When signs of excessive wear or damage are detected, the affected components (pins, bushings, or flanges) should be replaced promptly. Using worn or damaged components can lead to coupling failure, which can result in costly downtime and damage to other parts of the machinery. When replacing components, it is important to use parts that are compatible with the original coupling design to ensure proper fit and performance.

Advantages

Simplicity and Cost-Effectiveness: Pin and bushing couplings have a simple design with fewer components, making them easy to manufacture and inexpensive compared to more complex coupling types. This makes them an attractive option for applications where cost is a key consideration.

Reliable Torque Transmission: These couplings are capable of transmitting high torque loads efficiently, making them suitable for a wide range of industrial applications. Their robust construction ensures that they can withstand the stresses associated with torque transmission.

Misalignment Compensation: The flexible bushing elements allow the coupling to accommodate small to moderate amounts of angular, parallel, and axial misalignment, reducing the need for precise alignment during installation and accommodating misalignments that occur during operation.

Easy Installation and Maintenance: The simple design of pin and bushing couplings makes them easy to install and maintain. Maintenance requirements are minimal, and components can be easily replaced when necessary.

Vibration Damping: Depending on the bushing material used (e.g., rubber or polyurethane), pin and bushing couplings can provide effective vibration damping, reducing noise and protecting the machinery from vibration-related damage.

Limitations

Limited Misalignment Capacity: Pin and bushing couplings are designed to accommodate small to moderate amounts of misalignment. Excessive misalignment can lead to increased wear, vibration, and premature failure. For applications with large misalignments, more flexible coupling types such as universal joints or flexible disk couplings may be more suitable.

Wear of Bushings: The bushings are the most wear-prone component of the coupling, especially in high-speed or high-load applications. Regular inspection and replacement of bushings are required to ensure optimal performance.

Limited High-Speed Capability: Compared to some other coupling types, pin and bushing couplings have limited high-speed capability. At high speeds, the centrifugal forces generated by the pins can cause vibration and reduce the coupling’s service life. Therefore, they are not ideal for applications with very high rotational speeds.

Noise Generation: In some cases, especially when the bushings are worn or dry, pin and bushing couplings can generate noise during operation. Proper lubrication can help to reduce noise, but it may not eliminate it entirely.

While pin and bushing couplings have been in use for many years, ongoing advancements in materials science and manufacturing technology are leading to improvements in their design, performance, and durability. Some of the key emerging trends and innovations include:

Advanced Bushing Materials

Research and development in polymer science have led to the development of new bushing materials with enhanced properties. For example, advanced polyurethane compounds with higher temperature resistance, better wear resistance, and improved flexibility are being used in bushing manufacturing. These materials offer longer service life and better performance in harsh operating conditions compared to traditional bushing materials. Additionally, self-lubricating materials with improved lubrication properties are being developed, reducing the need for regular maintenance and extending the intervals between component replacements.

Lightweight Design

In applications where weight is a critical factor, such as in automotive and aerospace industries, lightweight pin and bushing couplings are being developed. These couplings use lightweight materials such as aluminum alloys or composite materials for the flanges and pins, reducing the overall weight of the coupling without compromising its strength and torque-carrying capacity. Lightweight couplings help to improve the efficiency of the machinery and reduce energy consumption.

Improved Manufacturing Processes

Advancements in manufacturing processes such as CNC machining, 3D printing, and precision casting are enabling the production of pin and bushing couplings with higher precision and better quality control. CNC machining ensures that the components are manufactured to tight tolerances, improving the fit and performance of the coupling. 3D printing, in particular, allows for the production of complex flange designs that are optimized for strength and weight, while also enabling rapid prototyping and customization of couplings for specific applications.

Smart Monitoring Capabilities

The integration of smart sensors into pin and bushing couplings is an emerging trend that enables real-time monitoring of the coupling’s performance. Sensors can be used to measure parameters such as temperature, vibration, and wear, providing early warning of potential issues such as excessive misalignment, worn bushings, or impending coupling failure. This allows for predictive maintenance, reducing downtime and improving the overall reliability of the power transmission system. Smart couplings are particularly useful in critical applications where unplanned downtime can result in significant costs.

Pin and bushing couplings are essential components in mechanical power transmission systems, offering a simple, reliable, and cost-effective solution for connecting rotating shafts. Their design, which incorporates flanges, pins, and bushings, enables efficient torque transmission while accommodating small to moderate misalignments, making them suitable for a wide range of industrial applications. The selection of appropriate materials for each component is critical to the coupling’s performance and durability, with options ranging from carbon steel and alloy steel for flanges and pins to rubber, polyurethane, and bronze for bushings.

Proper installation and regular maintenance are key to ensuring the optimal performance and longevity of pin and bushing couplings. By following correct installation procedures, performing regular inspections, and maintaining proper lubrication, users can minimize wear, reduce downtime, and extend the service life of the coupling. While pin and bushing couplings have some limitations, such as limited misalignment capacity and wear of bushings, ongoing advancements in materials and manufacturing technology are addressing these issues, leading to improved performance and new applications.

As industries continue to evolve and demand more efficient, reliable, and durable power transmission components, pin and bushing couplings are likely to remain a popular choice due to their inherent advantages. With the integration of smart monitoring capabilities and the development of advanced materials, these couplings are poised to become even more versatile and effective in meeting the needs of modern industrial applications.

« Pin And Bushing Couplings » Post Date: 2024/4/25 , https://www.rokeecoupling.net/tags/pin-and-bushing-couplings.html