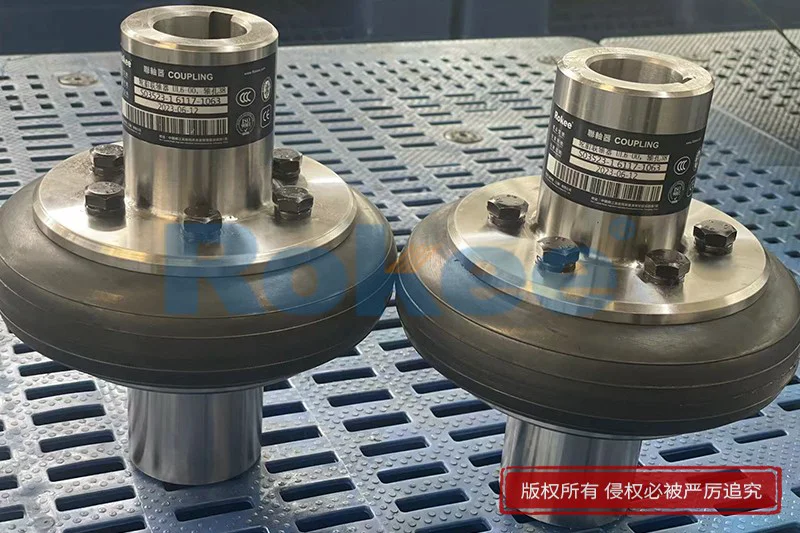

Rokee is a well-known high-quality supplier of Pump Tyre Couplings and technical services in China, customize pump tyre couplings according to user drawings, alternatively, if the user provides pump tyre couplings parameters, we can select the model and design drawings for you, support wholesale and export.

In the domain of industrial power transmission, especially in pump systems, the selection of appropriate coupling components directly affects operational efficiency, equipment lifespan, and overall system stability. Among the various flexible coupling solutions available, the pump tyre coupling (also known as rubber tyre coupling) has emerged as a specialized and reliable option, tailored to meet the unique operational demands of pump systems. Characterized by its excellent shock absorption, high misalignment compensation capability, and smooth torque transmission, this coupling type has become indispensable in numerous industrial sectors reliant on pump operations. This article provides an in-depth analysis of pump tyre couplings, covering their structural composition, working mechanism, key performance advantages, typical industrial applications, critical selection criteria, and maintenance strategies. By elaborating on these core aspects, the article aims to offer valuable insights for engineers, maintenance technicians, and industry professionals involved in the design, selection, and operation of pump systems.

A pump tyre coupling is a type of flexible coupling specifically designed for use in pump systems, engineered to connect the drive shaft (typically from an electric motor or diesel engine) to the pump shaft. Its primary function is to transmit torque efficiently while accommodating axial, radial, and angular misalignments between the two shafts, absorbing operational shocks and vibrations, and thereby safeguarding both the pump and the drive unit from potential damage. Unlike rigid couplings that require precise alignment and lack vibration damping properties, the pump tyre coupling utilizes an elastic tyre-shaped element as the core flexible component, which endows it with superior adaptability to the dynamic operating conditions common in pump systems.

The structural design of a pump tyre coupling is relatively compact yet robust, consisting of several key components that work in synergy to ensure optimal performance. The main components include:

- Two Flange Hubs: These are the rigid connecting parts that attach to the drive shaft and the pump shaft respectively. Usually fabricated from high-strength materials such as cast steel, ductile iron, or forged steel, the flange hubs are designed to withstand the torque and stress generated during pump operation. They are secured to the shafts via keyways, set screws, or taper lock bushings to ensure a firm and slip-free connection. The flanges are typically equipped with evenly distributed bolt holes around their circumference, which are used to fasten the tyre element.

- Tyre Elastic Element: This is the core flexible component of the coupling, shaped like a tyre (hence the name "tyre coupling"). Manufactured from high-quality elastic materials such as synthetic rubber (e.g., neoprene, nitrile butadiene rubber), polyurethane, or a composite of rubber and fabric reinforcement, the tyre element is responsible for absorbing shocks, dampening vibrations, and compensating for shaft misalignments. The tyre’s design—often featuring a curved or cylindrical profile—allows it to deform elastically under load, enabling smooth torque transmission while minimizing stress on the connected shafts and bearings.

- Connecting Bolts and Nuts: These fasteners are used to secure the tyre elastic element between the two flange hubs. The bolts pass through the bolt holes in the flanges and the corresponding holes in the tyre element, with nuts tightened to ensure a secure assembly. To prevent loosening during high-speed operation, lock washers or self-locking nuts are often used. The number and size of the bolts are determined by the coupling’s torque capacity and overall dimensions.

- Protective Cover (Optional): In some applications, a protective cover made of metal or plastic is installed around the coupling to shield the tyre element and moving parts from dust, debris, moisture, and other environmental contaminants. The cover also enhances operational safety by preventing accidental contact with rotating components, which is particularly important in industrial settings with high foot traffic.

The operational principle of a pump tyre coupling revolves around the elastic deformation of the tyre element, which enables torque transmission while accommodating misalignments and absorbing shocks. The working process can be broken down into three key stages: torque transmission, misalignment compensation, and shock/vibration absorption.

First, in terms of torque transmission: When the drive shaft (e.g., from an electric motor) rotates, it imparts rotational force to the drive-side flange hub, which is rigidly connected to it. The drive-side flange hub transfers this torque to the tyre elastic element via the connecting bolts. Since the tyre element is securely fastened to the pump-side flange hub, the torque is then transmitted from the tyre element to the pump-side hub, and ultimately to the pump shaft. This sequential transfer of torque ensures that the pump shaft rotates in synchronization with the drive shaft, enabling the pump to operate and perform its fluid-moving function.

Second, regarding misalignment compensation: Shaft misalignment is a common issue in pump systems, often caused by factors such as installation errors, thermal expansion of components during operation, shaft deflection under load, or foundation settlement. The pump tyre coupling addresses this by leveraging the elastic properties of the tyre element. When axial misalignment occurs (i.e., the shafts move toward or away from each other), the tyre element compresses or stretches elastically to accommodate the axial displacement. For radial misalignment (i.e., the shafts are offset parallel to each other), the tyre element bends slightly as the flanges rotate, bridging the gap between the offset shafts. In the case of angular misalignment (i.e., the shafts are not collinear and form an angle), the tyre element undergoes torsional deformation, allowing the two flanges to rotate at the same speed despite the angular offset. The ability to compensate for multiple types of misalignment is critical in pump systems, as it reduces wear on shafts, bearings, and seals, and prevents premature equipment failure.

Third, in terms of shock and vibration absorption: Pump systems—especially centrifugal pumps, reciprocating pumps, and diaphragm pumps—often generate significant vibrations and shock loads during operation. These vibrations can originate from the drive motor, the pump’s impeller imbalance, or fluid turbulence within the pump. The tyre elastic element of the coupling acts as a buffer, absorbing these shock loads and dampening vibrations. As the tyre element deforms elastically, it converts the kinetic energy of vibrations into heat (which is dissipated into the surrounding environment), thereby reducing the amplitude of vibrations transmitted between the drive unit and the pump. This not only improves the stability of the pump system but also reduces noise levels, creating a more favorable working environment.

It is important to note that the performance of the pump tyre coupling is heavily dependent on the integrity and material properties of the tyre element. Over time, the tyre element may degrade due to wear, aging, or exposure to harsh environmental conditions, which can compromise the coupling’s ability to transmit torque, compensate for misalignment, and absorb vibrations. Regular inspection and timely replacement of the tyre element are therefore essential to maintain optimal coupling performance.

Pump tyre couplings offer a range of unique advantages that make them particularly well-suited for pump system applications. These advantages stem from their specialized design and the properties of the tyre elastic element, and they include the following:

3.1 Excellent Vibration Damping and Shock Absorption

One of the most prominent advantages of pump tyre couplings is their superior vibration damping capability. The elastic tyre element, made from high-quality rubber or polyurethane, can effectively absorb and dissipate vibrations generated by both the drive motor and the pump. This is especially beneficial in pump systems where vibration can cause damage to sensitive components such as bearings, seals, and impellers. Additionally, the tyre element can absorb shock loads that occur during startup, shutdown, or sudden changes in operating conditions (e.g., sudden increases in fluid pressure), preventing these shocks from being transmitted to the drive unit or the pump, and thus extending the lifespan of both pieces of equipment.

3.2 High Misalignment Compensation Capacity

Pump tyre couplings are capable of accommodating relatively large amounts of axial, radial, and angular misalignment compared to many other types of flexible couplings. This is a critical advantage in pump systems, where achieving and maintaining perfect shaft alignment can be challenging due to factors such as thermal expansion (e.g., when the pump operates at high temperatures), shaft deflection under load, or minor shifts in the equipment foundation. The ability to compensate for misalignment reduces the need for precise alignment during installation, saving time and labor costs, and also minimizes wear on shafts, bearings, and seals during operation.

3.3 Smooth Torque Transmission and Low Noise Operation

The elastic tyre element of the coupling ensures smooth and continuous torque transmission between the drive shaft and the pump shaft. Unlike rigid couplings or some other flexible couplings that may transmit torque with intermittent jolts (especially when misaligned), the pump tyre coupling’s tyre element deforms gradually, resulting in a smooth transfer of rotational force. This smooth torque transmission not only improves the stability of the pump’s operation (e.g., reducing fluctuations in fluid flow rate and pressure) but also reduces operational noise. The dampening effect of the tyre element minimizes the noise generated by metal-to-metal contact or vibration, making the pump system quieter and more pleasant to work around.

3.4 Compact Design and Easy Installation

Pump tyre couplings feature a compact and lightweight design, which makes them suitable for use in pump systems with limited installation space (e.g., small-sized pumps or pump units installed in confined compartments). The simple structural composition—consisting of only two flanges, a tyre element, and connecting bolts—facilitates easy installation and disassembly. No specialized tools or complex procedures are required to assemble or disassemble the coupling, which reduces installation time and labor costs. Additionally, the compact design minimizes the coupling’s moment of inertia, which is beneficial for improving the dynamic performance of the pump system, especially during startup.

3.5 Cost-Effectiveness and Low Maintenance Requirements

Compared to more complex flexible couplings (such as gear couplings or disc couplings), pump tyre couplings are relatively inexpensive to manufacture and purchase. This cost advantage makes them an attractive option for both small-scale and large-scale pump applications. Furthermore, the maintenance requirements of pump tyre couplings are minimal. The only wear component is the tyre element, which is easy and affordable to replace. Regular maintenance typically involves only visual inspections of the tyre element for signs of wear, damage, or aging, and periodic tightening of the connecting bolts. No complex lubrication procedures are required (unlike gear couplings, which need regular lubrication to prevent wear), which further reduces maintenance costs and downtime.

3.6 Corrosion Resistance and Adaptability to Harsh Environments

The tyre element of pump tyre couplings can be manufactured from a variety of elastic materials with different properties, allowing the coupling to be adapted to various harsh operating environments. For example, nitrile butadiene rubber tyre elements offer excellent resistance to oils, fuels, and chemicals, making them suitable for pump systems used in oil and gas processing, chemical plants, or wastewater treatment facilities. Neoprene rubber tyre elements are resistant to ozone, weathering, and high temperatures, making them ideal for outdoor pump applications or systems operating at elevated temperatures. Additionally, the flange hubs can be coated with anti-corrosion materials (e.g., paint or galvanization) to enhance their resistance to moisture, saltwater, or other corrosive substances, further expanding the coupling’s applicability.

Due to their unique combination of performance advantages, pump tyre couplings are widely used in a variety of industrial sectors where pump systems play a critical role. Their ability to adapt to different operating conditions, accommodate misalignments, and absorb vibrations makes them suitable for both general-purpose and specialized pump applications. Some of the key industrial application areas are as follows:

4.1 Water and Wastewater Treatment Industry

In water and wastewater treatment plants, pump systems are used extensively for tasks such as water intake, filtration, aeration, and sludge transfer. These pump systems often operate in harsh environments, exposed to moisture, chemicals (e.g., disinfectants, coagulants), and varying temperatures. Pump tyre couplings are ideal for these applications due to their corrosion resistance (when equipped with appropriate tyre materials) and excellent vibration damping capabilities. They are commonly used in centrifugal pumps, submersible pumps, and sludge pumps, where they connect the drive motor to the pump shaft, ensuring reliable and efficient operation even in demanding conditions.

4.2 Oil and Gas Industry

The oil and gas industry relies heavily on pump systems for the extraction, transportation, and processing of crude oil, natural gas, and petroleum products. These pump systems often operate at high pressures, high temperatures, and in corrosive environments (exposed to crude oil, natural gas, and various chemicals). Pump tyre couplings with nitrile rubber or polyurethane tyre elements are widely used in this industry, as they offer excellent resistance to oils and chemicals. They are used in pumps such as reciprocating pumps, centrifugal pumps, and transfer pumps, connecting the drive units (e.g., electric motors or diesel engines) to the pump shafts. The coupling’s shock absorption capabilities are particularly beneficial in this industry, as they help to protect the pump and drive unit from the high shock loads generated during the pumping of viscous fluids or during sudden changes in operating conditions.

4.3 Chemical Industry

Chemical plants use a wide range of pump systems to transfer, mix, and process various chemicals (including corrosive, toxic, and viscous substances). These pump systems operate in highly corrosive environments and are subject to strict safety and reliability requirements. Pump tyre couplings are selected for these applications due to their ability to be customized with chemical-resistant tyre materials (e.g., nitrile rubber, fluororubber). They are used in chemical pumps such as diaphragm pumps, peristaltic pumps, and centrifugal chemical pumps, ensuring smooth torque transmission and protecting the pump and drive unit from vibrations and shocks. The compact design of pump tyre couplings also makes them suitable for use in the confined spaces often found in chemical plant equipment layouts.

4.4 Power Generation Industry

In power generation plants (including thermal power plants, hydropower plants, and nuclear power plants), pump systems are used for critical tasks such as boiler feedwater supply, cooling water circulation, and fuel oil transfer. These pump systems operate at high temperatures, high pressures, and require high reliability to ensure uninterrupted power generation. Pump tyre couplings are used in these applications to connect the drive motors to the pump shafts, leveraging their excellent vibration damping and misalignment compensation capabilities. They help to reduce wear on the pump’s bearings and seals, and ensure stable and efficient operation of the pump systems, which is essential for the overall reliability of the power generation process.

4.5 Agricultural Industry

The agricultural industry uses pump systems for irrigation, crop spraying, and water supply for livestock. These pump systems often operate in outdoor environments, exposed to weathering, dust, and varying temperatures, and may be subject to frequent movement and installation in different locations. Pump tyre couplings are well-suited for these applications due to their rugged design, easy installation, and resistance to weathering (when equipped with neoprene rubber tyre elements). They are commonly used in centrifugal irrigation pumps, diesel-powered water pumps, and sprayer pumps, connecting the drive unit to the pump shaft. The coupling’s ability to accommodate misalignments is particularly beneficial in agricultural applications, where precise installation conditions may be difficult to achieve.

4.6 Food and Beverage Industry

In the food and beverage industry, pump systems are used to transfer various fluids such as water, milk, juice, syrup, and edible oils. These pump systems require high levels of hygiene and must be easy to clean and maintain. Pump tyre couplings with food-grade rubber or polyurethane tyre elements are used in this industry, as they are non-toxic and meet the hygiene requirements of food and beverage processing. They are used in pumps such as centrifugal food pumps, positive displacement pumps, and homogenizer pumps, ensuring smooth and gentle torque transmission (to avoid damaging sensitive food products) and easy disassembly for cleaning and maintenance.

Selecting the right pump tyre coupling for a specific pump system is crucial to ensure optimal performance, reliability, and longevity. The selection process must take into account a range of factors, including the operational requirements of the pump system, environmental conditions, and the properties of the coupling itself. The key selection criteria are as follows:

5.1 Torque Capacity

The primary criterion for selecting a pump tyre coupling is its torque capacity, which must be sufficient to transmit the maximum torque generated by the drive unit (e.g., electric motor) to the pump shaft. It is essential to consider both the nominal torque (steady-state operating torque) and the peak torque (transient torque generated during startup, shutdown, or overload conditions). The coupling’s rated torque should be at least 1.2 to 1.5 times the maximum peak torque of the system to ensure a safety margin and prevent premature failure. Factors such as the power of the drive motor, the speed of the shafts, and the load characteristics of the pump (e.g., whether it is a centrifugal pump with low startup torque or a reciprocating pump with high startup torque) should be taken into account when calculating the required torque capacity.

5.2 Shaft Misalignment

The maximum misalignment that the coupling can accommodate must match the expected misalignment in the pump system. This includes axial, radial, and angular misalignment. It is important to measure or estimate the maximum possible misalignment in the system (considering factors such as installation errors, thermal expansion, shaft deflection, and foundation settlement) and select a coupling that can handle these values. Pump tyre couplings are available in different sizes and designs, with varying misalignment capacities. For example, larger couplings or those with thicker tyre elements may be able to accommodate greater radial and angular misalignment, while couplings with longer tyre elements may have higher axial misalignment capacity.

5.3 Operating Speed

The operating speed of the pump system (measured in revolutions per minute, RPM) is another important factor to consider. Pump tyre couplings have a maximum allowable speed, which is determined by the material properties of the tyre element, the design of the flanges, and the balance of the coupling. Operating the coupling above its maximum allowable speed can lead to excessive centrifugal forces, which may cause the tyre element to deform excessively, the connecting bolts to loosen, or even the coupling to fail. It is therefore essential to select a coupling whose maximum allowable speed is higher than the maximum operating speed of the pump system. For high-speed pump systems (e.g., centrifugal pumps operating at 3000 RPM or higher), couplings with lightweight, balanced flanges and high-strength tyre elements should be selected.

5.4 Environmental Conditions

The operating environment of the pump system has a significant impact on the performance and lifespan of the pump tyre coupling, particularly the tyre element. Key environmental factors to consider include temperature, humidity, exposure to chemicals (oils, fuels, acids, alkalis), dust, debris, and weathering (for outdoor applications). The tyre element material should be selected based on these conditions: for high-temperature environments (above 80°C), silicone rubber or fluororubber tyre elements are recommended; for environments exposed to oils or chemicals, nitrile rubber or polyurethane tyre elements are suitable; for outdoor applications, neoprene rubber tyre elements with ozone resistance are preferred. Additionally, if the environment is dusty or corrosive, a protective cover should be selected to shield the coupling components.

5.5 Shaft Dimensions

The coupling must be compatible with the dimensions of the drive shaft and the pump shaft, including the shaft diameter and the length of the shaft extension. The flange hubs of the coupling are available in a range of bore sizes to fit different shaft diameters. It is important to ensure that the bore size of the hubs matches the diameter of the shafts to achieve a tight fit and prevent slippage. Some couplings feature adjustable bore sizes (via taper lock bushings) to accommodate a range of shaft diameters, providing greater flexibility in selection. The length of the shaft extension must also be sufficient to allow the hubs to be securely attached to the shafts without interfering with other components (e.g., bearings, seals).

5.6 Tyre Element Material

The material of the tyre element is a critical factor that determines the coupling’s performance, durability, and adaptability to different environments. The most common tyre element materials and their properties are as follows:

- Neoprene Rubber: Offers good resistance to ozone, weathering, and moderate temperatures (up to 80°C). Suitable for outdoor applications and general-purpose pump systems. Provides excellent vibration damping and misalignment compensation.

- Nitrile Butadiene Rubber (NBR): Exhibits excellent resistance to oils, fuels, and chemicals. Suitable for pump systems in the oil and gas industry, chemical plants, and applications involving petroleum-based fluids. Operates well at temperatures up to 100°C.

- Polyurethane: Features high wear resistance, high tensile strength, and good resistance to abrasion and chemicals. Suitable for high-torque pump applications and environments with high levels of dust or debris. Operates at temperatures up to 80°C.

- Silicone Rubber: Offers excellent high-temperature resistance (up to 150°C) and good resistance to ozone and weathering. Suitable for pump systems operating at high temperatures (e.g., boiler feedwater pumps in power plants).

- Fluororubber (FKM): Provides superior resistance to high temperatures (up to 200°C) and a wide range of chemicals (including acids, alkalis, and solvents). Suitable for specialized pump applications in chemical plants and high-temperature industrial processes.

Proper maintenance is essential to ensure the long-term performance and reliability of pump tyre couplings. The maintenance requirements are relatively simple, but regular and systematic inspections and upkeep are necessary to prevent unexpected failures and extend the coupling’s lifespan. The key maintenance strategies are as follows:

6.1 Regular Visual Inspections

Visual inspections should be conducted periodically (e.g., monthly or quarterly, depending on the operating conditions) to check for signs of wear, damage, or deterioration of the coupling components. The focus of the inspection should be on the tyre element, which is the primary wear component. Key things to look for include cracks, tears, bulges, or hardening of the tyre element; loose or missing connecting bolts, nuts, or lock washers; corrosion or damage to the flange hubs; and any signs of oil or chemical contamination on the tyre element (which may indicate a leak in the pump system and can accelerate tyre degradation). If any of these issues are detected, immediate action should be taken (e.g., replacing the tyre element, tightening bolts).

6.2 Tyre Element Replacement

The tyre element is the only wear component of the pump tyre coupling and will eventually need to be replaced due to aging, wear, or damage. The replacement interval depends on the operating conditions (e.g., temperature, exposure to chemicals, operating speed) but typically ranges from 1 to 5 years. The replacement process is simple and involves the following steps:

1. Disconnect the power supply to the drive unit (e.g., electric motor) to ensure safety during maintenance.

2. Remove the protective cover (if installed) from the coupling.

3. Loosen and remove the connecting bolts and nuts that fasten the tyre element to the flange hubs.

4. Remove the old tyre element from between the two flange hubs.

5. Clean the flange hubs to remove any dust, debris, or oil contamination.

6. Install the new tyre element between the flange hubs, ensuring that it is properly aligned with the bolt holes in the flanges.

7. Reinstall the connecting bolts and nuts, tightening them evenly to the recommended torque (as specified by the coupling manufacturer).

8. Reattach the protective cover (if applicable) and restore the power supply to the drive unit.

It is important to use a tyre element of the same material and specifications as the original to ensure that the coupling’s performance is not compromised.

6.3 Checking and Tightening Connecting Bolts

The connecting bolts and nuts of the coupling may loosen over time due to vibration and thermal expansion. Periodic checks (e.g., monthly) should be conducted to ensure that the bolts are tight. If any loose bolts are found, they should be tightened to the recommended torque using a torque wrench. To prevent loosening, lock washers or self-locking nuts should be used, and damaged bolts or nuts should be replaced immediately.

6.4 Shaft Alignment Checks

Although pump tyre couplings can accommodate misalignments, periodic checks of shaft alignment are recommended (e.g., every 6 months or after maintenance work) to ensure that the misalignment does not exceed the coupling’s allowable limit. Excessive misalignment can cause premature wear of the tyre element and increase stress on the shafts, bearings, and seals. Shaft alignment can be checked using simple tools such as a straightedge and feeler gauge for basic alignment checks, or more precise tools such as a laser alignment tool for accurate measurements. If the misalignment exceeds the allowable limit, adjustments should be made to the drive unit or the pump to correct the alignment.

6.5 Protection Against Environmental Contaminants

To extend the lifespan of the tyre element and other coupling components, it is important to protect the coupling from environmental contaminants such as dust, debris, moisture, and chemicals. In dusty or dirty environments, a protective cover should be installed and kept clean. In environments exposed to chemicals or oils, the coupling should be inspected regularly for signs of contamination, and any spilled chemicals or oil should be cleaned off immediately. Additionally, in outdoor applications, the coupling should be protected from direct sunlight and extreme weather conditions (e.g., heavy rain, snow) to prevent premature aging of the tyre element.

Pump tyre couplings are a critical component in pump systems, offering a unique combination of excellent vibration damping, high misalignment compensation, smooth torque transmission, and cost-effectiveness. Their specialized design—centered around the elastic tyre element—makes them particularly well-suited to the dynamic and often harsh operating conditions of pump systems across various industries. From water and wastewater treatment to oil and gas processing, from power generation to agriculture, pump tyre couplings play an essential role in ensuring the reliable and efficient operation of pump systems, protecting equipment from damage, and reducing maintenance costs and downtime.

The selection of the right pump tyre coupling requires careful consideration of factors such as torque capacity, misalignment requirements, operating speed, environmental conditions, shaft dimensions, and tyre element material. By selecting a coupling that is tailored to the specific needs of the pump system, engineers and maintenance professionals can optimize the system’s performance and extend its lifespan. Proper maintenance—including regular visual inspections, timely tyre element replacement, checking and tightening of bolts, and shaft alignment checks—is also essential to ensure the long-term reliability of the coupling.

As industrial pump systems continue to evolve, with increasing demands for higher efficiency, greater reliability, and lower environmental impact, pump tyre couplings are likely to undergo further improvements in material technology and design. Advances in elastic materials (e.g., more durable and chemical-resistant rubbers and polyurethanes) and manufacturing processes (e.g., precision molding of tyre elements) will further enhance the performance and versatility of pump tyre couplings, making them even more indispensable in the industrial landscape. By staying abreast of these advancements and adhering to best practices in selection and maintenance, industry professionals can continue to leverage the benefits of pump tyre couplings to optimize their pump systems and achieve operational excellence.

« Pump Tyre Couplings » Post Date: 2024/4/25 , https://www.rokeecoupling.net/tags/pump-tyre-couplings.html