Rokee is a well-known high-quality supplier of Shim Couplings and technical services in China, customize shim couplings according to user drawings, alternatively, if the user provides shim couplings parameters, we can select the model and design drawings for you, support wholesale and export.

In the intricate network of industrial power transmission systems, couplings play a pivotal role in connecting rotating shafts, enabling efficient torque transfer while addressing misalignments and mitigating operational stresses. Among the diverse spectrum of coupling technologies, the shim coupling has emerged as a specialized and reliable solution, distinguished by its unique use of thin, flexible shims as the core compensating element. Designed to balance precision, durability, and adaptability, shim couplings are particularly valued in applications where controlled flexibility, minimal backlash, and resistance to harsh conditions are paramount. Unlike elastic couplings reliant on polymer components or rigid couplings requiring exact alignment, shim couplings leverage the elastic deformation of metallic shims to accommodate misalignments, making them suitable for a range of industrial settings—from precision machinery to heavy-duty processing equipment. This article comprehensively explores the structural design, operating principles, material selection, performance characteristics, industrial applications, and maintenance practices of shim couplings, shedding light on their unique value proposition in modern power transmission systems.

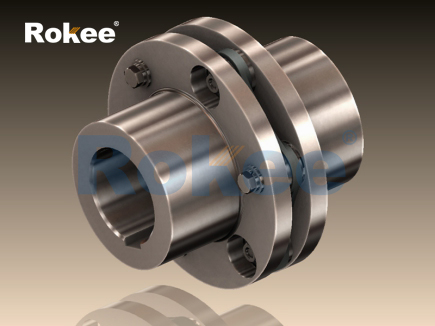

The structural design of a shim coupling is characterized by its simplicity, robustness, and focus on controlled flexibility. A typical shim coupling consists of four core components: two shaft hubs, a set of thin metallic shims, clamping plates, and fastening elements (such as bolts and nuts). The hubs are precision-machined components designed to attach securely to the driving and driven shafts, utilizing connection methods like keyway fits, spline connections, or interference fits to ensure slip-free torque transmission. Hubs are typically cylindrical or flanged in shape, with mounting surfaces tailored to interface with the shims and clamping plates.

The defining component of the shim coupling is the set of metallic shims. These shims are thin, flat, and usually circular or rectangular in shape, fabricated from high-strength, ductile metals. The number of shims in an assembly varies based on the application’s torque requirements and misalignment compensation needs—more shims enhance flexibility for misalignment but may reduce torsional stiffness, while fewer shims increase torque capacity but limit flexibility. The shims are stacked in a parallel or alternating orientation between the two hubs, creating a flexible joint that allows for controlled deformation. In some designs, the shims may feature precision-cut slots or perforations to optimize their flexibility and stress distribution, ensuring uniform deformation under load.

Clamping plates and fastening elements are critical for securing the shim stack between the hubs. The clamping plates, typically made of the same material as the hubs, apply uniform pressure across the shim stack, ensuring a tight and consistent connection. Bolts are inserted through aligned holes in the hubs, shim stack, and clamping plates, and tightened with nuts to create a rigid assembly that maintains the integrity of the shim stack during operation. The placement of bolts is carefully engineered to distribute the clamping force evenly, preventing localized stress concentrations that could damage the shims or hubs. Some advanced designs may incorporate spring washers or lock nuts to prevent bolt loosening due to vibration, enhancing the coupling’s operational reliability.

Variations in shim coupling design exist to cater to specific application demands. For example, "single-shim" designs are used for light-duty applications with minimal misalignment requirements, while "multi-shim" assemblies are preferred for heavy-duty or high-misalignment scenarios. Additionally, some shim couplings feature tapered hubs for easier shaft installation, or corrosion-resistant coatings for use in harsh environments. The modular nature of shim coupling design also allows for easy replacement of shims, enabling quick maintenance and adaptation to changing operational needs.

The operating mechanism of a shim coupling revolves around the elastic deformation of the metallic shims, which enables torque transmission while accommodating three primary types of shaft misalignment: angular misalignment (shafts inclined relative to each other), parallel misalignment (shafts offset horizontally), and axial displacement (shafts moving toward or away from each other). When the driving shaft rotates, torque is transferred to the driving hub, which in turn imparts rotational force to the shim stack. The shims, being rigidly clamped between the hubs, transmit this torque to the driven hub and ultimately to the driven shaft. This torque transmission process is efficient, with minimal energy loss due to the rigid connection between the components.

The key to the shim coupling’s functionality is the controlled elastic deformation of the shims during misalignment. When the shafts are misaligned, the shims bend or twist slightly, absorbing the misalignment without transmitting excessive stresses to the shafts, bearings, or other components. For angular misalignment, the shims on one side of the coupling compress slightly while those on the opposite side stretch, allowing the hubs to rotate at an angle relative to each other. Parallel misalignment is accommodated by the lateral bending of the shims, which bridge the offset between the shafts. Axial displacement is absorbed by the axial stretching or compression of the shim stack, ensuring that the coupling remains fully engaged even as the shafts move axially.

Another important aspect of the operating mechanism is the minimal backlash exhibited by shim couplings. Backlash, the clearance between mating components, is virtually eliminated due to the tight clamping of the shims between the hubs. This lack of backlash makes shim couplings ideal for applications requiring precise positioning and synchronization, such as CNC machine tools, robotics, and automated production lines. The rigid connection between the shims and hubs ensures that the driven shaft responds immediately to changes in the driving shaft’s rotation, enhancing the accuracy and repeatability of the mechanical system.

Shim couplings also exhibit effective torsional vibration damping capabilities. Torsional vibrations, common in rotating machinery such as engines, pumps, and compressors, can cause noise, reduce efficiency, and lead to premature component failure. The metallic shims, due to their inherent material properties and thin profile, act as a torsional spring, absorbing and dissipating vibrational energy through their elastic deformation. This damping effect is particularly beneficial in applications with variable speed operation or intermittent loads, where vibrations are more pronounced. Unlike elastic couplings that use rubber components, which degrade over time and lose damping performance, shim couplings maintain consistent vibration damping characteristics throughout their service life.

Material selection is a critical factor in determining the performance, durability, and application suitability of shim couplings. Each component (hubs, shims, clamping plates, and fasteners) has distinct functional requirements, and the materials chosen must withstand mechanical stresses, environmental conditions, and operational demands. The following sections outline the common materials used for each component and the factors influencing their selection.

Hubs and clamping plates are typically fabricated from high-strength metallic materials that offer rigidity, fatigue resistance, and wear resistance. The most commonly used materials include carbon steel, alloy steel, and stainless steel. Carbon steel, such as A36 or 45# steel, is widely used for general-purpose applications due to its high strength, low cost, and good machinability. It is suitable for moderate torque loads in industries such as general manufacturing and material handling. Alloy steel, such as 40Cr or 35CrMo, offers enhanced strength, toughness, and fatigue resistance, making it ideal for heavy-duty applications with high torque requirements, such as in steel mills, mining equipment, and large compressors. Stainless steel, such as 304 or 316, is used in corrosive environments, such as chemical processing plants, marine applications, and food processing facilities, due to its excellent corrosion resistance.

Shims, being the core flexible component, require materials with high ductility, elastic resilience, and resistance to fatigue. The most commonly used materials for shims include spring steel, stainless steel, and titanium. Spring steel, such as 65Mn or SAE 1070, is a popular choice due to its excellent elastic properties and fatigue resistance. It can withstand repeated elastic deformation without permanent damage, making it suitable for applications with frequent misalignments. Stainless steel shims offer the added benefit of corrosion resistance, making them suitable for harsh environments. Titanium shims are used in high-performance applications, such as aerospace and automotive racing, due to their exceptional strength-to-weight ratio and resistance to extreme temperatures. However, the high cost of titanium limits its use to specialized applications.

Fasteners such as bolts and nuts are typically made from carbon steel, alloy steel, or stainless steel. Carbon steel fasteners are used for general-purpose applications, while alloy steel fasteners are preferred for heavy-duty applications due to their higher strength. Stainless steel fasteners are used in corrosive environments to prevent rust and corrosion. Lock washers or thread-locking compounds are often used to ensure that the fasteners remain tight during operation, even under high vibration.

In some specialized applications, additional materials may be used to enhance the coupling’s performance. For example, in high-temperature applications, Inconel or Hastelloy may be used for shims and hubs to withstand extreme temperatures. In applications requiring electrical insulation, non-metallic shims made from materials such as fiberglass or ceramic may be used, although this is less common in traditional shim coupling designs.

Shim couplings exhibit a unique set of performance characteristics that make them well-suited for a range of industrial applications. One of the most notable characteristics is their excellent misalignment compensation capability. Depending on the design and material of the shims, shim couplings can accommodate angular misalignments up to 2 degrees, parallel misalignments up to 1 millimeter, and axial displacements up to 5 millimeters. This flexibility eliminates the need for precise shaft alignment during installation, reducing setup time and labor costs. Additionally, the controlled elastic deformation of the shims ensures that misalignments are absorbed without transmitting excessive stresses to the shafts or other components, extending the service life of the machinery.

Another key performance characteristic is their high torque capacity. Shim couplings, despite their flexible design, can transmit significant torques due to the high-strength materials used in their construction. The torque capacity ranges from a few hundred newton-meters to several thousand newton-meters, depending on the size of the hubs, the number and thickness of the shims, and the material of the components. This makes them suitable for both light-duty and heavy-duty applications, from small electric motors to large industrial machinery.

Shim couplings also offer minimal backlash and high precision, making them ideal for applications requiring accurate positioning and synchronization. The tight clamping of the shims between the hubs eliminates any clearance between the components, ensuring that the driven shaft responds instantly to changes in the driving shaft’s rotation. This precision is critical in applications such as CNC machine tools, robotics, and automated assembly lines, where even small amounts of backlash can compromise the accuracy of the operation.

Resistance to harsh operating conditions is another important performance characteristic of shim couplings. The metallic construction of the coupling (hubs, shims, and clamping plates) makes it resistant to extreme temperatures, chemicals, oils, and solvents. Unlike elastic couplings that can melt, harden, or degrade in harsh conditions, shim couplings maintain consistent performance over a wide temperature range (from -50°C to 500°C, depending on the material). This makes them suitable for use in environments such as chemical processing plants, high-temperature industrial furnaces, and marine applications.

However, shim couplings also have some limitations. One of the main limitations is their relatively high cost compared to simple couplings such as pin and bush couplings. The precision machining required for the hubs and shims, as well as the use of high-strength materials, contributes to the higher cost. Another limitation is their limited ability to dampen high-amplitude vibrations compared to elastic couplings. While they offer effective torsional vibration damping, they are less effective at absorbing high-frequency or large-amplitude lateral vibrations. Additionally, shim couplings require regular inspection to ensure that the shims are not damaged or fatigued, as this can compromise their performance.

Due to their unique performance characteristics, shim couplings find applications across a diverse range of industries. Their ability to transmit high torques, accommodate misalignments, maintain precision, and resist harsh conditions makes them suitable for a wide variety of rotating machinery. The following sections highlight the key industrial sectors where shim couplings are commonly employed.

The machine tool industry is one of the largest users of shim couplings. CNC machine tools, such as lathes, milling machines, and grinders, require precise torque transmission and minimal backlash to ensure accurate cutting and machining operations. Shim couplings are ideal for these applications as they provide the necessary precision and misalignment compensation, ensuring that the tool head moves exactly as programmed. Additionally, their resistance to cutting fluids and coolants makes them suitable for use in the harsh environment of machine shops.

The aerospace industry extensively uses shim couplings in aircraft engines, auxiliary power units (APUs), and flight control systems. In these applications, weight reduction, high precision, and resistance to extreme temperatures are critical. Titanium or stainless steel shim couplings are used to transmit torque between rotating components while minimizing weight and accommodating misalignments. Their ability to withstand high temperatures and vibration ensures the reliability of critical aircraft systems during flight.

The chemical and petrochemical industry uses shim couplings in pumps, compressors, and agitators. These applications require couplings that can withstand corrosive chemicals, high pressures, and high temperatures. Stainless steel or nickel-based shim couplings are particularly suitable here, as their corrosion-resistant properties ensure long-term reliability and prevent contamination of process fluids. The minimal backlash and high precision of shim couplings also help to ensure the efficient operation of pumps and compressors, reducing energy consumption and operational costs.

The automotive industry utilizes shim couplings in high-performance vehicles, such as racing cars and electric vehicles (EVs). In racing cars, lightweight shim couplings made from titanium or aluminum are used to transmit high torques from the engine to the transmission, improving acceleration and overall performance. In EVs, shim couplings are used in the drivetrain to connect the electric motor to the wheels, ensuring efficient torque transmission and reliable operation. Their vibration damping capabilities also help to reduce noise and improve ride comfort in electric vehicles.

Other industrial applications of shim couplings include power generation (gas turbines, steam turbines, and generators), mining and mineral processing (crushers, conveyors, and separators), marine propulsion systems, and robotics. In each of these applications, the coupling’s ability to transmit torque reliably, accommodate misalignments, maintain precision, and resist harsh conditions makes it a practical and effective solution.

Proper maintenance is essential to ensure the reliable operation and long service life of shim couplings. Regular maintenance helps to identify and address potential issues such as shim fatigue, bolt loosening, and misalignment before they lead to coupling failure and machinery downtime. The following are key maintenance considerations for shim couplings.

Regular inspection is the foundation of effective shim coupling maintenance. Inspections should be conducted at regular intervals (depending on the operating conditions and manufacturer’s recommendations) to check for signs of wear, damage, or fatigue. During inspection, the coupling should be visually examined for cracks or deformation in the shims, hubs, or clamping plates. The fasteners should be checked to ensure they are tight, and any signs of corrosion should be noted. Additionally, the coupling should be checked for excessive vibration, which may indicate misalignment or shim damage.

Shim replacement is a critical maintenance task for shim couplings. Over time, the shims may become fatigued due to repeated elastic deformation, leading to a loss of flexibility or even failure. The frequency of shim replacement depends on the operating conditions, such as the magnitude of misalignments, the speed of rotation, and the environmental conditions. When replacing shims, it is important to use the correct type, size, and material of shims recommended by the coupling manufacturer. The old shims should be removed carefully to avoid damaging the hubs or clamping plates, and the new shims should be stacked and clamped properly to ensure uniform pressure distribution.

Bolt tightening and inspection are also important maintenance tasks. Vibrations during operation can cause the bolts to loosen, reducing the clamping force on the shim stack and compromising the coupling’s performance. Regularly checking and tightening the bolts to the recommended torque specification helps to maintain the integrity of the coupling. In some cases, thread-locking compounds or lock washers may be used to prevent bolt loosening, and these should be inspected and replaced as needed.

Shaft alignment should be checked and adjusted regularly to minimize stress on the shim coupling and other components. While shim couplings can accommodate misalignments, excessive or prolonged misalignment can accelerate shim fatigue and reduce the coupling’s service life. Shaft alignment can be checked using tools such as a straightedge, feeler gauge, or laser alignment tool. If misalignment is detected, the machinery should be adjusted to correct the alignment.

Finally, in corrosive or harsh environments, additional maintenance measures may be required. This may include applying corrosion-resistant coatings to the coupling components, regularly cleaning the coupling to remove dust, debris, or chemical residues, and using stainless steel or other corrosion-resistant materials for replacement parts.

Shim couplings have established themselves as a high-performance, reliable solution for power transmission in a wide range of industrial applications. Their unique design, featuring thin metallic shims as the core flexible element, offers a compelling combination of precision, misalignment compensation, high torque capacity, and resistance to harsh operating conditions. The careful selection of materials, from cost-effective spring steel to premium titanium and nickel-based alloys, ensures that shim couplings can be tailored to meet the specific requirements of any application, from general manufacturing to high-performance aerospace systems.

While shim couplings have some limitations, such as higher cost compared to simple couplings and limited high-amplitude vibration damping, their advantages—including minimal backlash, high precision, durability, and resistance to harsh conditions—make them a preferred choice for applications where performance and reliability are critical. They are widely employed in industries such as machine tools, aerospace, chemical processing, and automotive, playing a crucial role in ensuring the smooth and efficient operation of rotating machinery.

Proper maintenance, including regular inspection, shim replacement, bolt tightening, and shaft alignment, is essential to maximize the service life and performance of shim couplings. With ongoing advancements in material science and manufacturing technology—such as the development of new high-strength, fatigue-resistant alloys and more precise machining techniques—shim couplings are poised to become even more versatile and efficient, further enhancing their value in modern industrial systems.

In summary, shim couplings represent a specialized and effective solution for power transmission needs where precision, flexibility, and durability are paramount. Their growing popularity across diverse industries is a testament to their unique performance characteristics and reliability, making them an indispensable component of the global industrial infrastructure.

« Shim Couplings » Post Date: 2024/4/25 , https://www.rokeecoupling.net/tags/shim-couplings.html