Rokee is a well-known high-quality supplier of Rubber Tyre Couplings and technical services in China, customize rubber tyre couplings according to user drawings, alternatively, if the user provides rubber tyre couplings parameters, we can select the model and design drawings for you, support wholesale and export.

In the realm of mechanical transmission systems, coupling devices serve as critical components that connect two rotating shafts, enabling the transfer of torque while accommodating various forms of misalignment. Among the diverse range of couplings available, the rubber tyre coupling has emerged as a widely adopted solution across numerous industrial sectors. Characterized by its flexibility, vibration damping capabilities, and simple structural design, this type of coupling plays an indispensable role in ensuring the smooth and efficient operation of machinery. This article aims to provide a comprehensive overview of rubber tyre couplings, exploring their working principles, key structural features, material properties, applications, installation and maintenance practices, as well as recent technological advancements.

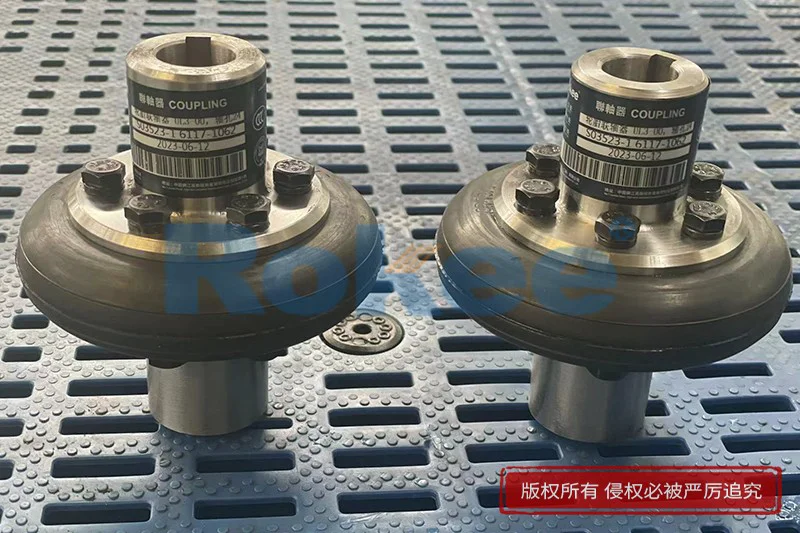

To understand the functionality of rubber tyre couplings, it is essential to first grasp their fundamental working principle. At its core, a rubber tyre coupling relies on the elastic deformation of a rubber tyre element to transmit torque between two shafts. The coupling typically consists of three main components: two metal flanges (or hubs) that are attached to the driving and driven shafts, respectively, and a rubber tyre that connects these two flanges. When the driving shaft rotates, it imparts torque to the connected flange, which in turn transfers this torque to the rubber tyre. The rubber tyre, due to its elastic nature, deforms slightly under the applied torque and transmits the rotational force to the other flange, thereby driving the driven shaft. A key advantage of this design is its ability to accommodate axial, radial, and angular misalignment between the two shafts. Axial misalignment refers to the linear displacement of one shaft relative to the other along the axis of rotation, while radial misalignment is the lateral offset between the shaft centers. Angular misalignment occurs when the two shafts are not perfectly colinear, forming an angle between their axes. The rubber tyre’s flexibility allows it to absorb these misalignments without causing excessive stress on the shafts or other transmission components, thus reducing wear and extending the service life of the machinery.

The structural design of rubber tyre couplings varies slightly depending on the specific application requirements, but the basic configuration remains consistent. The metal flanges are typically made of high-strength steel or cast iron, which provides the necessary rigidity to withstand the transmitted torque. These flanges are equipped with mounting holes that allow them to be bolted securely to the shafts using keys, splines, or set screws. The rubber tyre, which is the heart of the coupling, is designed to fit snugly between the two flanges. In some designs, the tyre is bonded directly to metal sleeves that attach to the flanges, while in others, the tyre features integral studs or bolts that pass through the flanges, securing the assembly. The shape of the rubber tyre also varies, with common designs including cylindrical, conical, and bell-shaped tyres. Each shape is optimized for specific performance characteristics, such as higher torque capacity, greater misalignment tolerance, or improved vibration damping. Additionally, some rubber tyre couplings are equipped with protective covers to shield the rubber element from external contaminants, such as dust, moisture, and chemicals, which can degrade the rubber over time.

The performance of a rubber tyre coupling is heavily dependent on the properties of the rubber material used in the tyre element. Rubber materials suitable for this application must possess a unique combination of elasticity, tensile strength, abrasion resistance, and resistance to environmental factors. The most commonly used rubber materials include natural rubber, nitrile rubber (NBR), ethylene propylene diene monomer (EPDM), and silicone rubber. Natural rubber offers excellent elasticity and low-temperature flexibility, making it ideal for applications operating in moderate environments. Nitrile rubber, on the other hand, exhibits superior resistance to oil and fuel, making it suitable for use in automotive and industrial applications where exposure to petroleum-based products is common. EPDM rubber is known for its excellent resistance to weathering, ozone, and high temperatures, making it a preferred choice for outdoor or high-temperature applications. Silicone rubber offers the highest temperature resistance among these materials, capable of withstanding temperatures ranging from -60°C to 250°C, and is often used in specialized applications such as aerospace and high-temperature industrial processes. In addition to the base rubber material, various additives are incorporated to enhance specific properties, such as carbon black for increased tensile strength and wear resistance, plasticizers for improved flexibility, and antioxidants to prevent degradation due to oxidation.

The versatility of rubber tyre couplings makes them suitable for a wide range of applications across multiple industries. One of the most common applications is in the automotive industry, where they are used in the transmission systems of cars, trucks, and buses. In these applications, the coupling helps to absorb vibrations generated by the engine, reducing noise and improving the overall driving experience. Additionally, it accommodates the slight misalignments that may occur between the engine and the transmission due to manufacturing tolerances or thermal expansion. Another major application area is in industrial machinery, such as pumps, compressors, motors, and conveyors. In pump systems, for example, the rubber tyre coupling helps to compensate for the misalignment between the pump shaft and the motor shaft, reducing the load on the bearings and extending the service life of the pump. In conveyor systems, the coupling absorbs the shock loads that occur during startup and operation, ensuring smooth power transmission and preventing damage to the conveyor components. Rubber tyre couplings are also widely used in the agricultural industry, where they are employed in tractors, harvesters, and other farm equipment. The harsh operating conditions in agriculture, including uneven terrain and frequent shock loads, make the vibration damping and misalignment compensation capabilities of rubber tyre couplings particularly valuable. Additionally, these couplings are used in the marine industry, where they help to transmit power from the engine to the propeller while accommodating the misalignments caused by the movement of the vessel.

Proper installation and maintenance are crucial to ensuring the optimal performance and long service life of rubber tyre couplings. The installation process begins with the careful alignment of the two shafts. While rubber tyre couplings can accommodate a certain degree of misalignment, excessive misalignment can lead to increased stress on the rubber tyre, resulting in premature failure. Therefore, it is essential to use precision alignment tools, such as laser alignment devices or dial indicators, to ensure that the shafts are aligned within the manufacturer’s recommended tolerances. The next step is to securely attach the flanges to the shafts. This typically involves using keys to ensure a tight fit between the flange and the shaft, followed by tightening the set screws or bolts to the specified torque. It is important to avoid over-tightening the bolts, as this can cause deformation of the flanges or damage to the rubber tyre. Once the coupling is installed, a final check should be performed to ensure that the rubber tyre is properly seated and that there is no interference between the coupling components and other parts of the machinery.

Regular maintenance is essential to detect potential issues early and prevent unexpected failures. One of the key maintenance tasks is the regular inspection of the rubber tyre for signs of wear, damage, or degradation. This includes checking for cracks, tears, hardening, or softening of the rubber, which can indicate that the tyre is approaching the end of its service life. Additionally, the bolts and fasteners should be inspected regularly to ensure that they are tight and not松动. Loose bolts can cause excessive vibration and misalignment, leading to premature failure of the coupling. Another important maintenance practice is the lubrication of the coupling components, although some rubber tyre couplings are designed to be maintenance-free and do not require lubrication. For couplings that do require lubrication, it is important to use the correct type of lubricant, as specified by the manufacturer, to prevent damage to the rubber tyre. In environments where the coupling is exposed to dust, moisture, or chemicals, regular cleaning of the coupling components is also recommended to remove contaminants that can degrade the rubber. Finally, it is important to replace the rubber tyre at the first sign of significant wear or damage. Delaying replacement can lead to more serious problems, such as shaft misalignment, bearing failure, or even damage to the connected machinery, which can result in costly downtime.

In recent years, technological advancements have led to improvements in the design and performance of rubber tyre couplings. One of the key areas of innovation is the development of new rubber materials with enhanced properties. For example, researchers have developed composite rubber materials that combine the elasticity of rubber with the strength of synthetic fibers, resulting in couplings with higher torque capacity and improved durability. Additionally, advancements in manufacturing processes, such as injection molding and compression molding, have allowed for more precise control over the shape and properties of the rubber tyre, ensuring consistent performance and quality. Another area of innovation is the integration of smart technology into rubber tyre couplings. Some modern couplings are equipped with sensors that monitor parameters such as temperature, vibration, and torque, providing real-time data on the coupling’s performance. This data can be transmitted to a central monitoring system, allowing maintenance personnel to detect potential issues before they lead to failure. This predictive maintenance approach helps to reduce downtime and improve the overall reliability of the machinery. Furthermore, there has been a growing focus on the design of more compact and lightweight rubber tyre couplings, which are particularly suitable for applications where space is limited, such as in electric vehicles and small industrial machinery.

Despite their many advantages, rubber tyre couplings also have some limitations that should be considered when selecting a coupling for a specific application. One of the main limitations is their relatively lower torque capacity compared to rigid couplings or metal flexible couplings. Therefore, they may not be suitable for high-torque applications, such as large industrial gearboxes or heavy-duty mining equipment. Another limitation is the limited temperature range of some rubber materials. Exposure to temperatures outside the recommended range can cause the rubber to degrade rapidly, leading to premature failure. Additionally, rubber tyre couplings are not suitable for applications where they are exposed to strong chemicals, such as acids or solvents, unless a specialized chemical-resistant rubber material is used. Finally, the rubber tyre is a wear component that requires periodic replacement, which can result in maintenance costs and downtime. However, these limitations are often outweighed by the benefits of rubber tyre couplings, such as their vibration damping capabilities, misalignment compensation, and simple installation, making them the preferred choice for many applications.

In conclusion, rubber tyre couplings are essential components in mechanical transmission systems, offering a unique combination of flexibility, vibration damping, and misalignment compensation. Their simple structural design, ease of installation, and versatility make them suitable for a wide range of applications across automotive, industrial, agricultural, and marine industries. The performance of these couplings is heavily dependent on the properties of the rubber material used, with different materials being optimized for specific environmental conditions and performance requirements. Proper installation and regular maintenance are crucial to ensuring the optimal performance and long service life of rubber tyre couplings, while recent technological advancements have led to improvements in their design, performance, and reliability. Despite their limitations, rubber tyre couplings continue to play a vital role in ensuring the smooth and efficient operation of machinery, and their importance is likely to grow as new materials and technologies are developed. As industries continue to evolve and demand more efficient and reliable transmission systems, rubber tyre couplings will remain a key solution for meeting these challenges.

« Rubber Tyre Couplings » Post Date: 2024/4/25 , https://www.rokeecoupling.net/tags/rubber-tyre-couplings.html