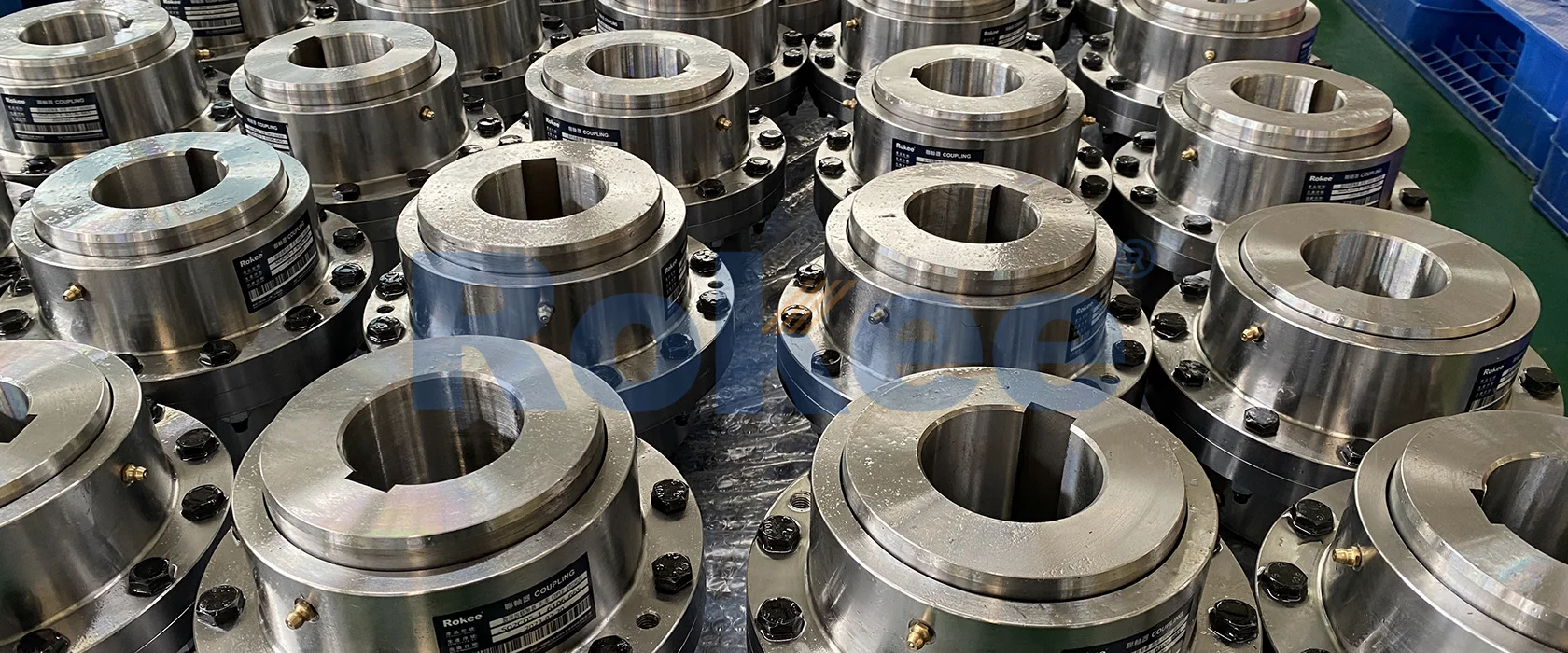

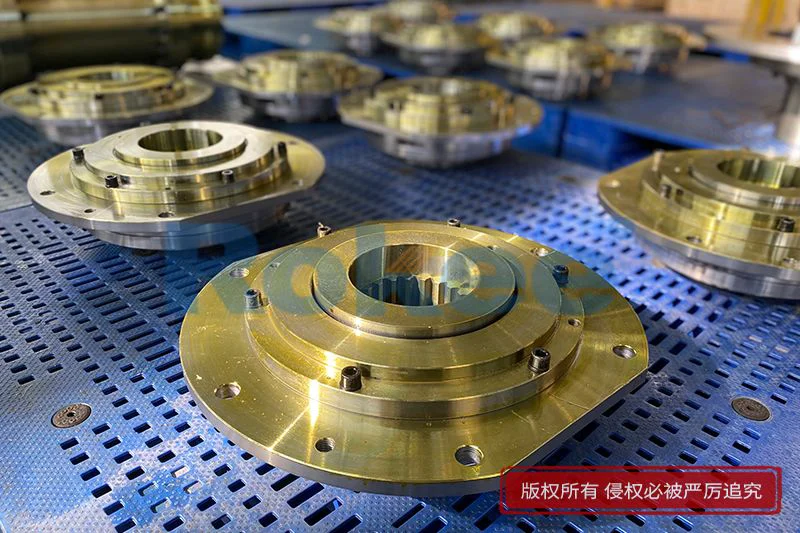

Rokee is a well-known high-quality supplier of Spherical Gear Couplings and technical services in China, customize spherical gear couplings according to user drawings, alternatively, if the user provides spherical gear couplings parameters, we can select the model and design drawings for you, support wholesale and export.

In the realm of mechanical power transmission, couplings serve as critical components that bridge rotating shafts, enabling torque transfer while accommodating misalignments and mitigating operational stresses. Among the diverse array of coupling types, spherical gear couplings stand out for their unique combination of high torque capacity, angular misalignment tolerance, and structural robustness. Designed to operate in demanding industrial environments, these couplings play an indispensable role in ensuring the reliability and efficiency of rotating machinery across multiple sectors. This article delves into the fundamental design characteristics, working principles, key advantages, applications, maintenance considerations, and future developments of spherical gear couplings, providing a comprehensive overview of their role in modern mechanical systems.

Spherical gear couplings are a type of rigid-flexible coupling that utilizes spherical gear teeth to facilitate torque transmission between two shafts while accommodating angular, parallel, and axial misalignments. Unlike traditional rigid couplings that require near-perfect shaft alignment, spherical gear couplings are engineered with a degree of flexibility that makes them suitable for applications where misalignment is inevitable due to installation errors, thermal expansion, or structural deflection.

The core structure of a spherical gear coupling typically consists of four main components: two gear hubs, an outer sleeve (or housing), and a set of spherical gear teeth. The gear hubs are attached to the respective shafts via keyways, shrink fits, or bolted connections, ensuring a secure torque transfer interface. Each hub features a set of gear teeth machined on a spherical surface, which meshes with corresponding teeth on the inner surface of the outer sleeve. The spherical geometry of the gear teeth is the defining feature of this coupling type, as it allows for relative angular movement between the hubs and the sleeve without compromising the meshing integrity of the gear teeth.

The gear teeth of spherical gear couplings are typically cut using precision machining processes to ensure accurate meshing and minimize wear. Common tooth profiles include involute and cycloidal curves, each selected based on the specific application requirements such as torque capacity, speed, and misalignment range. The number of teeth, module (tooth size), and pressure angle are key design parameters that determine the coupling’s torque-carrying capacity and operational smoothness. Additionally, the outer sleeve is often designed with a split structure to facilitate easy installation and removal, which is particularly beneficial in large-scale industrial applications where equipment accessibility is limited.

Another important design consideration is the material selection for spherical gear couplings. Given their role in transmitting high torques and withstanding dynamic loads, the components are typically fabricated from high-strength alloy steels such as 40CrNiMoA or 35CrMo, which offer excellent tensile strength, fatigue resistance, and wear resistance. The gear teeth are often subjected to surface hardening treatments, such as carburizing, quenching, and tempering, to enhance their surface hardness and prolong service life. In some cases, corrosion-resistant materials or coatings may be used for couplings operating in harsh environments, such as marine or chemical processing facilities.

The operational principle of spherical gear couplings revolves around the meshing of spherical gear teeth, which enables torque transmission while accommodating various types of shaft misalignment. When torque is applied to the input shaft, it is transferred to the corresponding gear hub, whose spherical teeth engage with the teeth on the outer sleeve. The outer sleeve then transmits the torque to the output gear hub, which in turn drives the output shaft. The spherical geometry of the teeth allows for relative movement between the two hubs and the sleeve, which is crucial for compensating for misalignments.

Angular misalignment, which occurs when the axes of the two shafts intersect at an angle, is the primary type of misalignment accommodated by spherical gear couplings. The spherical teeth enable the gear hubs to pivot relative to the outer sleeve, allowing the shafts to operate at angles typically ranging from 10 to 20 degrees, depending on the coupling design. This is in contrast to many other coupling types, such as parallel gear couplings, which have a much lower angular misalignment capacity (usually less than 5 degrees).

In addition to angular misalignment, spherical gear couplings can also accommodate small amounts of parallel misalignment (offset between shaft axes) and axial misalignment (relative axial movement of shafts). Parallel misalignment is compensated for by the slight radial movement of the gear hubs within the outer sleeve, while axial misalignment is absorbed by the axial play in the gear meshing. However, it should be noted that the primary function of spherical gear couplings is to handle angular misalignment, and excessive parallel or axial misalignment can lead to increased wear and reduced coupling life.

Another key aspect of the working principle is the distribution of load across the gear teeth. The spherical meshing ensures that the load is evenly distributed over multiple teeth, which reduces the stress on individual teeth and enhances the coupling’s torque-carrying capacity. This even load distribution also contributes to smoother operation and lower noise levels, making spherical gear couplings suitable for high-speed applications.

Spherical gear couplings offer a range of advantages that make them preferred for many industrial applications, particularly those involving high torque, misalignment, and harsh operating conditions. One of the most significant advantages is their high angular misalignment tolerance. As mentioned earlier, these couplings can accommodate angular misalignments of up to 20 degrees, which is significantly higher than that of most other rigid and flexible couplings. This makes them ideal for use in machinery where shaft alignment is difficult to maintain, such as in heavy-duty industrial equipment, construction machinery, and agricultural machinery.

Another major advantage is their high torque capacity. The robust design of the gear hubs and outer sleeve, combined with the even load distribution across the spherical teeth, allows spherical gear couplings to transmit large amounts of torque. This makes them suitable for high-power applications, such as in steel mills, mining equipment, and power generation facilities, where the transmission of high torque is critical.

Spherical gear couplings also exhibit excellent durability and long service life. The use of high-strength materials and surface hardening treatments for the gear teeth ensures that they can withstand the wear and tear associated with continuous operation under high loads. Additionally, the enclosed design of the outer sleeve protects the gear teeth from dust, dirt, and other contaminants, which further extends their service life and reduces the need for frequent maintenance.

Operational smoothness and low noise are also notable advantages of spherical gear couplings. The precise meshing of the spherical teeth minimizes vibration and noise during operation, which is beneficial for both the machinery and the working environment. This is particularly important in applications where noise levels are a concern, such as in food processing facilities, pharmaceutical plants, and indoor manufacturing operations.

Furthermore, spherical gear couplings are relatively easy to install and maintain. The split outer sleeve design allows for easy installation and removal without the need to disassemble the entire shaft system, which saves time and labor costs. Routine maintenance typically involves periodic lubrication to ensure smooth operation and prevent wear, which is a straightforward process.

Due to their unique combination of advantages, spherical gear couplings find applications in a wide range of industries and machinery types. One of the primary application areas is the steel industry, where they are used in rolling mills, continuous casting machines, and steelmaking equipment. In rolling mills, for example, spherical gear couplings transmit torque from the motor to the rolling rolls, accommodating the misalignment caused by the heavy loads and thermal expansion of the rolls. Their high torque capacity and durability make them well-suited for the harsh operating conditions in steel mills, where temperatures are high and loads are extreme.

The mining industry is another major user of spherical gear couplings. Mining equipment such as crushers, conveyors, and excavators require reliable torque transmission in dusty, dirty, and vibration-prone environments. Spherical gear couplings are used in these applications to connect the motor to the equipment’s rotating components, accommodating the misalignment caused by the uneven terrain and heavy loads. Their robust design and enclosed structure protect them from the harsh mining environment, ensuring continuous operation and minimizing downtime.

Construction machinery, such as bulldozers, excavators, and cranes, also relies on spherical gear couplings. These machines operate in rugged environments where shaft misalignment is common due to the dynamic loads and structural deflection. Spherical gear couplings are used in the transmission systems of these machines, enabling the transfer of high torque while accommodating the necessary misalignments. Their durability and resistance to wear make them ideal for the demanding conditions of construction sites.

The power generation industry is another important application area. In power plants, spherical gear couplings are used in turbines, generators, and auxiliary equipment. They transmit torque from the turbine to the generator, accommodating the misalignment caused by thermal expansion and the large size of the equipment. Their high torque capacity and reliable operation are critical for ensuring the efficient and continuous generation of electricity.

Other applications of spherical gear couplings include agricultural machinery (such as tractors and harvesters), marine equipment (such as ship propeller shafts), and industrial pumps and compressors. In each of these applications, the coupling’s ability to handle misalignment, transmit high torque, and operate reliably in harsh conditions makes it an essential component.

Proper maintenance is essential for ensuring the long service life and reliable operation of spherical gear couplings. The primary maintenance task is periodic lubrication. The gear teeth and other moving parts of the coupling require adequate lubrication to reduce friction, prevent wear, and dissipate heat. The type of lubricant used depends on the operating conditions, such as temperature, speed, and load. Common lubricants include mineral oils, synthetic oils, and greases. It is important to follow the manufacturer’s recommendations regarding the type of lubricant and the lubrication interval.

Regular inspection is another important maintenance practice. Inspections should be conducted to check for signs of wear, damage, or misalignment. Signs of wear may include excessive play in the coupling, abnormal noise or vibration during operation, and leakage of lubricant. If any of these signs are detected, the coupling should be inspected more thoroughly to determine the cause and take appropriate action, such as replacing worn components or realigning the shafts.

Shaft alignment is also a critical maintenance consideration. While spherical gear couplings can accommodate misalignment, excessive misalignment can lead to increased wear and reduced coupling life. Therefore, it is important to ensure that the shafts are aligned as accurately as possible during installation and to check the alignment periodically during operation. Shaft alignment can be performed using various tools, such as dial indicators, laser alignment systems, and optical alignment tools.

In addition to lubrication, inspection, and alignment, it is also important to ensure that the coupling components are properly tightened. Loose fasteners can lead to excessive vibration, misalignment, and damage to the coupling. Therefore, fasteners such as bolts and nuts should be checked periodically and tightened to the recommended torque values.

Finally, in the event of component wear or damage, it is important to replace the affected components with high-quality replacements. Using substandard components can compromise the performance and reliability of the coupling, leading to premature failure and potential damage to the connected machinery.

As industrial machinery becomes more advanced, there is a growing demand for spherical gear couplings that offer higher performance, greater efficiency, and improved reliability. One of the key trends in the development of spherical gear couplings is the use of advanced materials and manufacturing processes. For example, the use of composite materials, such as carbon fiber-reinforced polymers, is being explored to reduce the weight of the coupling while maintaining its strength and durability. This is particularly beneficial for applications where weight reduction is critical, such as in aerospace and automotive industries.

Another trend is the integration of smart technologies into spherical gear couplings. Smart couplings equipped with sensors can monitor various operating parameters, such as temperature, vibration, and torque, in real-time. This allows for predictive maintenance, where potential issues can be detected before they lead to coupling failure. For example, sensors can detect increased vibration caused by worn gear teeth, alerting maintenance personnel to replace the teeth before they fail completely. This not only reduces downtime but also improves the overall efficiency of the machinery.

Advancements in machining technology are also driving the development of spherical gear couplings. The use of computer numerical control (CNC) machining and 3D printing allows for more precise manufacturing of the spherical gear teeth, improving the meshing accuracy and reducing wear. 3D printing, in particular, enables the production of complex geometries that are difficult to achieve with traditional machining processes, opening up new possibilities for the design of spherical gear couplings with enhanced performance.

Additionally, there is a growing focus on improving the energy efficiency of spherical gear couplings. By reducing friction between the gear teeth and optimizing the design of the coupling, manufacturers are able to reduce energy losses during torque transmission. This is particularly important in the context of global efforts to reduce energy consumption and carbon emissions.

Finally, the development of customized spherical gear couplings for specific applications is another emerging trend. As industries become more specialized, there is a need for couplings that are tailored to the unique requirements of a particular application. This includes couplings designed for extreme temperatures, high speeds, or corrosive environments. Manufacturers are increasingly offering customized solutions to meet these specific needs.

Spherical gear couplings are essential components in modern mechanical power transmission systems, offering a unique combination of high torque capacity, angular misalignment tolerance, durability, and operational smoothness. Their robust design and ability to operate in harsh industrial environments make them suitable for a wide range of applications, including steel mills, mining equipment, construction machinery, and power generation facilities. Proper maintenance, including periodic lubrication, inspection, and shaft alignment, is critical for ensuring their long service life and reliable operation.

Looking to the future, advancements in materials, manufacturing processes, and smart technologies are expected to further enhance the performance and efficiency of spherical gear couplings. The integration of sensors for predictive maintenance, the use of advanced composite materials, and the development of customized solutions will enable these couplings to meet the evolving needs of the industrial sector. As machinery becomes more advanced and demanding, spherical gear couplings will continue to play a vital role in ensuring the reliability and efficiency of rotating equipment, contributing to the overall productivity and sustainability of industrial operations.

« Spherical Gear Couplings » Post Date: 2024/4/25 , https://www.rokeecoupling.net/tags/spherical-gear-couplings.html