Rokee is a well-known high-quality supplier of Spherical Couplings and technical services in China, customize spherical couplings according to user drawings, alternatively, if the user provides spherical couplings parameters, we can select the model and design drawings for you, support wholesale and export.

In the realm of mechanical power transmission, couplings serve as critical components that connect two shafts, enabling the transfer of torque while accommodating various forms of misalignment. Among the diverse range of coupling types, spherical couplings stand out for their unique ability to handle significant angular, axial, and radial misalignments with minimal friction and wear. This article delves into the fundamental principles, structural characteristics, material considerations, applications, and evolutionary trends of spherical couplings, shedding light on their indispensable role in modern mechanical systems.

A spherical coupling, at its core, is a mechanical device designed to transmit rotational motion and torque between two shafts that are not perfectly aligned. Unlike rigid couplings, which require precise coaxial alignment, spherical couplings leverage a spherical contact surface to allow relative movement between the connected shafts. This spherical geometry is the defining feature that enables the coupling to accommodate angular misalignment—where the shafts are inclined relative to each other—axial misalignment (axial displacement along the shaft axis), and radial misalignment (lateral offset between the shaft centers). The ability to handle multiple forms of misalignment simultaneously makes spherical couplings particularly valuable in applications where shaft alignment is challenging to maintain, such as in dynamic or vibrating environments.

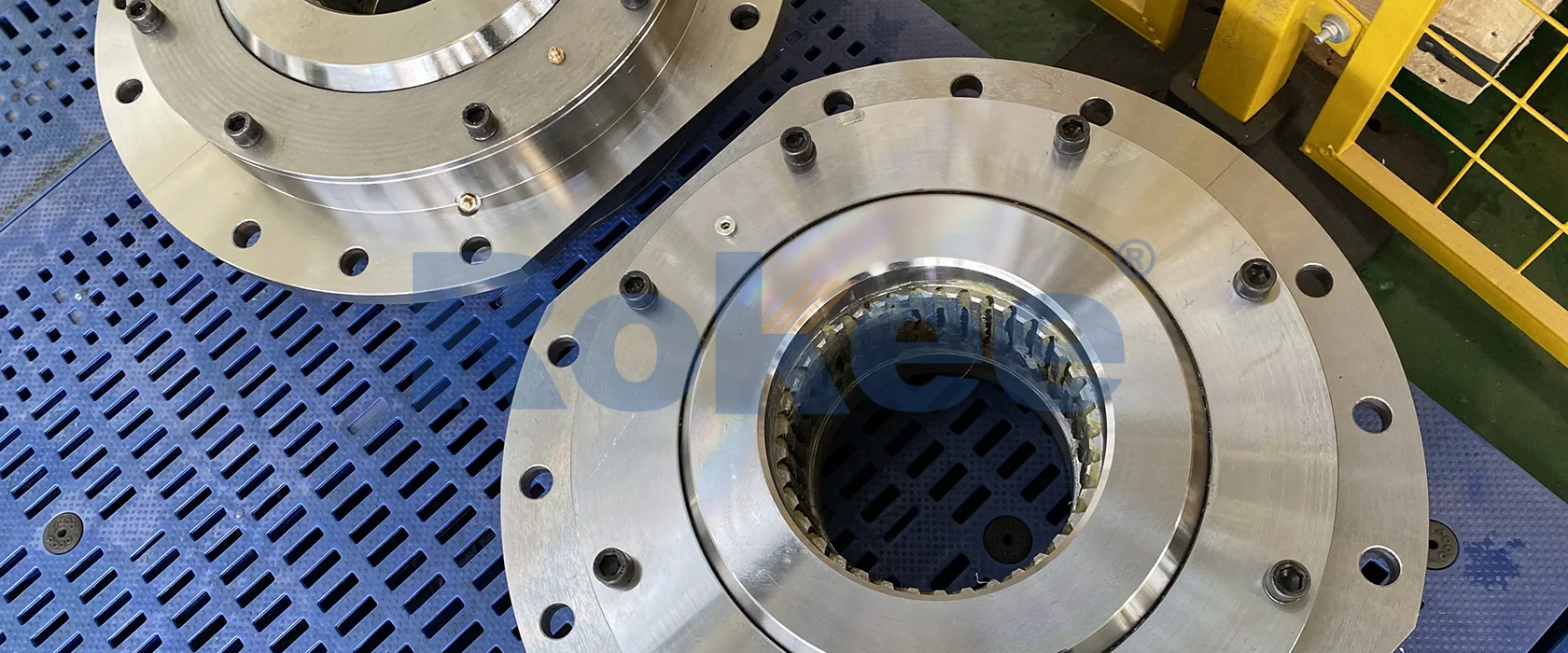

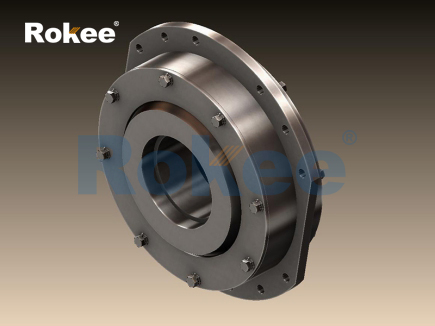

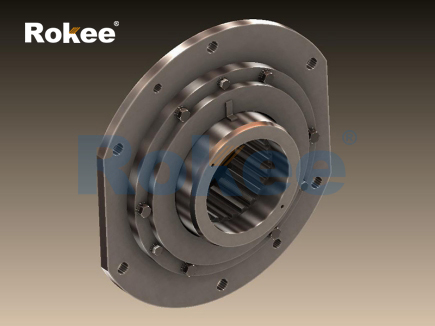

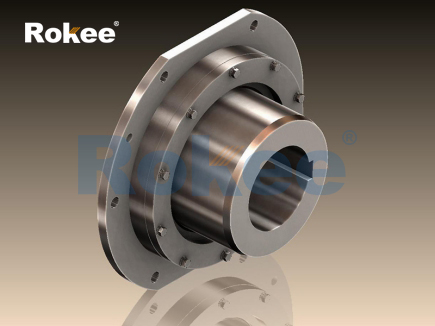

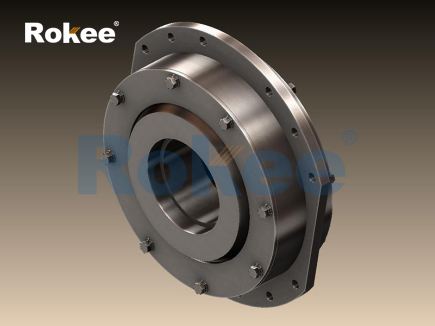

To understand the functionality of spherical couplings, it is essential to examine their basic structural components. While designs may vary depending on specific application requirements, most spherical couplings consist of three primary parts: an input shaft adapter, a spherical element, and an output shaft adapter. The spherical element, often referred to as the ball or socket, is the central component that facilitates misalignment. One of the adapters (typically the input side) features a spherical convex surface, while the other (output side) has a corresponding spherical concave surface that mates with the convex surface. The interface between these two spherical surfaces is engineered to ensure smooth relative motion, often with the inclusion of a lubrication system to reduce friction and prevent premature wear. In some designs, additional components such as retaining rings, seals, or bearings may be integrated to enhance stability, protect against contaminants, or further reduce friction.

The working principle of a spherical coupling revolves around the relative motion permitted by the spherical contact. When torque is applied to the input shaft, the convex spherical surface of the input adapter transmits this torque to the concave surface of the output adapter through the spherical element. As the shafts misalign—whether angularly, axially, or radially—the spherical surfaces slide or rotate against each other, maintaining continuous contact and torque transmission. The key advantage of this design is that the contact area between the spherical surfaces remains relatively consistent even during misalignment, ensuring uniform torque distribution and minimizing stress concentrations. This consistent contact also helps to reduce vibration and noise, which is crucial for maintaining the smooth operation of mechanical systems.

Material selection is a critical aspect of spherical coupling design, as it directly impacts the coupling’s performance, durability, and suitability for specific applications. The choice of materials depends on factors such as the required torque capacity, operating speed, environmental conditions (e.g., temperature, humidity, presence of corrosive substances), and load type (static vs. dynamic). Common materials used for the spherical elements and adapters include high-strength alloy steels, stainless steel, and aluminum alloys. Alloy steels are preferred for high-torque applications due to their excellent mechanical strength and wear resistance. Stainless steel is chosen for applications where corrosion resistance is essential, such as in marine or food processing environments. Aluminum alloys, on the other hand, are used in lightweight applications where weight reduction is a priority, such as in aerospace or automotive components.

In addition to the base materials, surface treatments and coatings are often applied to enhance the performance of spherical couplings. For example, hardening treatments (such as carburizing, nitriding, or induction hardening) can increase the surface hardness of the spherical contact surfaces, reducing wear and extending the service life of the coupling. Coatings such as Teflon or molybdenum disulfide may be used to improve lubricity, reducing friction and enabling smooth operation even in low-lubrication or high-temperature environments. Seals and gaskets, typically made from elastomers or synthetic rubbers, are also important for protecting the internal components from dust, dirt, and moisture, which can degrade performance and cause premature failure.

The versatility of spherical couplings makes them suitable for a wide range of applications across various industries. One of the most common applications is in automotive systems, where they are used in drive shafts, steering systems, and suspension components. In drive shafts, spherical couplings accommodate the angular misalignment that occurs as the suspension moves, ensuring consistent torque transmission from the engine to the wheels. In steering systems, they enable the transfer of rotational motion from the steering wheel to the steering rack, even as the wheels turn and the suspension articulates. The ability to handle dynamic misalignment and high torque makes spherical couplings ideal for automotive applications, where reliability and performance are critical.

Another major application area for spherical couplings is in industrial machinery, such as pumps, compressors, conveyors, and machine tools. In pumps and compressors, which often operate at high speeds and handle varying loads, spherical couplings accommodate the misalignment between the motor shaft and the pump/compressor shaft, reducing stress on the bearings and other components. This helps to improve the efficiency and lifespan of the machinery, minimizing downtime and maintenance costs. In conveyors, spherical couplings are used to connect the drive motor to the conveyor belt system, allowing for misalignment caused by the long length of the conveyor or slight variations in installation. In machine tools, such as milling machines and lathes, spherical couplings ensure precise torque transmission and motion control, even with minor misalignments, which is essential for maintaining the accuracy of the machined parts.

Aerospace and defense applications also rely heavily on spherical couplings, where they are used in aircraft engines, landing gear systems, and missile guidance systems. In aircraft engines, spherical couplings connect various rotating components, such as the turbine and compressor shafts, accommodating the thermal expansion and contraction that occurs during engine operation. The high-temperature and high-pressure environment of aircraft engines requires spherical couplings to be made from advanced materials with excellent heat resistance and mechanical strength. In landing gear systems, spherical couplings enable the movement of the landing gear struts and wheels, ensuring smooth and reliable operation during takeoff and landing. In missile guidance systems, they are used in the control surfaces, providing precise motion control even under extreme conditions.

Medical equipment is another area where spherical couplings play a vital role. In devices such as surgical robots, MRI machines, and patient positioning systems, spherical couplings enable precise and smooth motion control, which is essential for the accuracy and safety of medical procedures. Surgical robots, for example, use spherical couplings in their articulated arms, allowing for a wide range of motion while maintaining precise control over the surgical instruments. MRI machines require components that are non-magnetic and can withstand the high magnetic fields and radiofrequency radiation, making stainless steel or non-magnetic alloy spherical couplings the ideal choice. Patient positioning systems use spherical couplings to adjust the position of the patient table, ensuring comfort and accuracy during imaging or surgery.

Over the years, spherical coupling design has evolved significantly, driven by advancements in materials science, manufacturing technology, and the growing demands of modern applications. One of the key trends in the evolution of spherical couplings is the development of lightweight and compact designs. As industries such as aerospace and automotive strive to reduce weight and improve fuel efficiency, manufacturers are developing spherical couplings using lightweight materials such as aluminum alloys and composite materials. These materials not only reduce the overall weight of the coupling but also offer excellent strength-to-weight ratios, making them suitable for high-performance applications.

Another important trend is the integration of advanced lubrication systems and self-lubricating materials. Traditional spherical couplings require regular lubrication to reduce friction and wear, which can be time-consuming and costly in applications where access is limited. To address this, manufacturers have developed self-lubricating spherical couplings that use solid lubricants (such as graphite or molybdenum disulfide) embedded in the spherical contact surfaces. These self-lubricating couplings eliminate the need for regular lubrication, reducing maintenance requirements and improving reliability. Advanced lubrication systems, such as oil circulation systems with filters and coolers, are also being integrated into high-performance spherical couplings used in industrial and aerospace applications, ensuring consistent lubrication even under high-speed and high-temperature conditions.

The use of advanced manufacturing technologies, such as additive manufacturing (3D printing), has also revolutionized spherical coupling design and production. Additive manufacturing allows for the creation of complex geometries that are difficult or impossible to produce using traditional manufacturing methods, such as casting or machining. This enables the design of spherical couplings with optimized contact surfaces, improved load distribution, and reduced weight. Additive manufacturing also allows for the production of custom spherical couplings tailored to specific application requirements, reducing lead times and costs. Additionally, the use of 3D scanning and simulation tools has improved the design process, allowing engineers to simulate the performance of spherical couplings under various operating conditions and optimize the design for maximum efficiency and durability.

The development of smart spherical couplings is another emerging trend in the industry. Smart couplings integrate sensors and monitoring systems that provide real-time data on the coupling’s performance, such as torque, temperature, vibration, and misalignment. This data can be used to predict potential failures, schedule maintenance proactively, and optimize the operation of the mechanical system. For example, sensors embedded in the spherical coupling can detect abnormal vibration patterns, which may indicate excessive wear or misalignment, alerting maintenance personnel before a failure occurs. Smart spherical couplings are particularly valuable in critical applications such as power generation, aerospace, and medical equipment, where downtime can have severe consequences.

Despite their many advantages, spherical couplings also have some limitations that need to be considered in their application. One of the main limitations is their relatively lower torque capacity compared to rigid couplings or other types of flexible couplings, such as jaw couplings or disc couplings. This makes them less suitable for applications requiring extremely high torque transmission. Another limitation is the potential for backlash, which is the amount of free movement between the connected shafts. Backlash can affect the precision of motion control, making spherical couplings less ideal for applications where precise positioning is critical, such as in some machine tool applications. However, advancements in design and manufacturing have helped to minimize backlash in modern spherical couplings, expanding their range of applications.

In terms of maintenance, while self-lubricating spherical couplings reduce the need for regular lubrication, they still require periodic inspection to ensure that the seals are intact, the spherical surfaces are not excessively worn, and the coupling is functioning properly. In applications where the coupling is exposed to harsh environments, such as high temperatures, corrosive substances, or abrasive dust, more frequent inspection and maintenance may be necessary. Proper installation is also critical for the performance and lifespan of spherical couplings. Improper alignment during installation can lead to excessive wear, increased vibration, and premature failure. It is essential to follow the manufacturer’s installation guidelines and use the appropriate tools to ensure that the coupling is installed correctly.

Looking to the future, the evolution of spherical couplings is likely to continue, driven by the increasing demand for more efficient, reliable, and intelligent mechanical systems. Advancements in materials science will lead to the development of even more advanced materials with improved heat resistance, corrosion resistance, and strength-to-weight ratios. The integration of artificial intelligence (AI) and machine learning into smart spherical couplings will enable more accurate predictive maintenance, as AI algorithms can analyze the real-time data from the sensors to identify patterns and predict failures with greater precision. Additionally, the use of additive manufacturing will become more widespread, allowing for the production of even more complex and optimized spherical coupling designs.

Another future trend is the development of spherical couplings for renewable energy applications, such as wind turbines and solar tracking systems. Wind turbines, which operate in harsh outdoor environments and experience significant dynamic loads and misalignment, require couplings that are durable, reliable, and capable of handling high torque. Spherical couplings are well-suited for this application, as they can accommodate the misalignment between the wind turbine’s rotor shaft and the generator shaft, reducing stress on the components and improving efficiency. Solar tracking systems use spherical couplings to adjust the position of the solar panels, ensuring that they are always aligned with the sun to maximize energy output. The growing demand for renewable energy will drive the development of spherical couplings specifically tailored to these applications.

In conclusion, spherical couplings are essential components in modern mechanical systems, offering unique advantages in handling multiple forms of misalignment while transmitting torque efficiently and reliably. Their diverse range of applications, from automotive and industrial machinery to aerospace and medical equipment, highlights their versatility and importance. The evolution of spherical couplings, driven by advancements in materials, manufacturing, and sensor technology, has led to improved performance, reduced maintenance requirements, and the development of smart and lightweight designs. As industries continue to demand more efficient and reliable mechanical systems, spherical couplings will undoubtedly play an increasingly important role, with future developments focusing on advanced materials, intelligent monitoring, and customization for emerging applications such as renewable energy. Understanding the fundamentals, applications, and evolutionary trends of spherical couplings is crucial for engineers, designers, and maintenance professionals, enabling them to select and utilize the right coupling for their specific needs, ensuring the optimal performance and lifespan of their mechanical systems.

« Spherical Couplings » Post Date: 2024/4/25 , https://www.rokeecoupling.net/tags/spherical-couplings.html