Rokee is a well-known high-quality supplier of Tire Shaft Couplings and technical services in China, customize tire shaft couplings according to user drawings, alternatively, if the user provides tire shaft couplings parameters, we can select the model and design drawings for you, support wholesale and export.

In the field of mechanical power transmission, the demand for couplings that can balance torque transmission efficiency with vibration damping and misalignment compensation has driven the development of various flexible coupling designs. Among these, the tire shaft coupling—also referred to as a rubber tire coupling or elastic tire coupling—has emerged as a reliable and versatile solution, leveraging the elastic properties of a tire-like element to achieve smooth power transfer while protecting connected machinery. Distinguished by its unique tire-shaped elastomeric component, this type of coupling excels in absorbing shocks, dampening vibrations, and accommodating multiple types of shaft misalignments, making it widely applicable in industries ranging from automotive and manufacturing to marine and renewable energy. This article provides a comprehensive overview of tire shaft couplings, exploring their structural composition, operating mechanisms, key advantages, typical applications, and essential maintenance practices, to shed light on their critical role in enhancing the reliability and efficiency of modern mechanical systems.

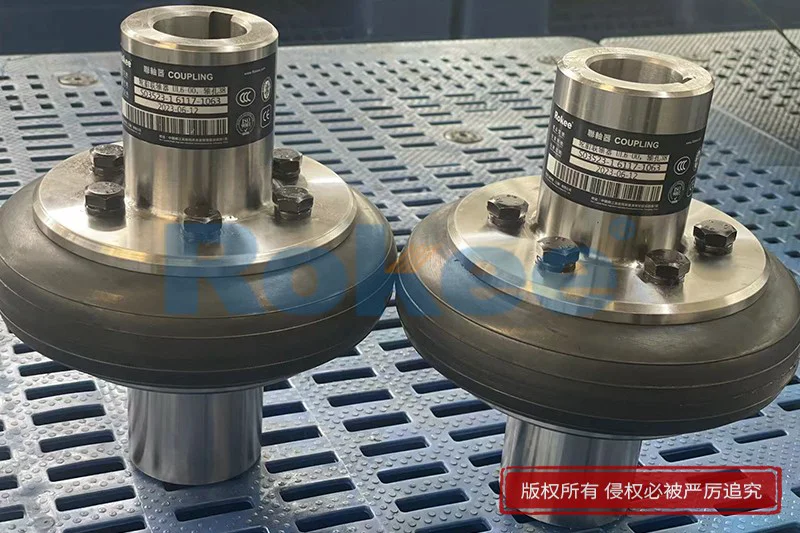

The tire shaft coupling features a distinctive structure that combines rigid connecting components with a flexible elastomeric tire element, striking a balance between torque transmission capability and operational flexibility. While specific designs may vary to suit different application requirements, the fundamental structure of a tire shaft coupling consists of four core components: two metal hubs, a tire-shaped elastomeric element (the "tire"), connecting bolts or studs, and protective covers (in some configurations). These components work synergistically to ensure efficient torque transfer while providing the necessary flexibility to accommodate misalignments and absorb shocks.

The metal hubs are critical load-bearing components designed to mount securely on the driver and driven shafts. Typically fabricated from high-strength materials such as carbon steel, alloy steel, or cast iron, the hubs are engineered to withstand the torque loads and shear forces encountered during operation. Each hub is equipped with a precision-machined bore that matches the diameter of the respective shaft, and they are secured to the shafts using common fastening methods such as keyways, set screws, or clamp collars. The outer circumference of the hubs is designed with flanges or lugs that feature bolt holes, which are used to attach the elastomeric tire element. The design of the hubs ensures a rigid connection to the shafts, preventing relative rotation and ensuring efficient torque transfer to the tire element.

The tire-shaped elastomeric element is the defining component of the tire shaft coupling, responsible for its flexible characteristics, vibration damping, and misalignment compensation capabilities. This element is typically made from high-quality synthetic rubber compounds, such as neoprene, nitrile rubber, or polyurethane, which offer excellent elasticity, wear resistance, and resistance to environmental factors such as oil, moisture, and temperature variations. The tire element is designed with a hollow, cylindrical shape similar to a small tire, with metal inserts or reinforcement layers embedded at its inner circumference to facilitate secure attachment to the hubs. These inserts feature bolt holes that align with the holes on the hub flanges, allowing the tire to be bolted firmly between the two hubs. In some advanced designs, the tire element may incorporate fabric or steel cord reinforcements to enhance its tensile strength and torque capacity, making it suitable for heavy-duty applications.

Connecting bolts or studs serve as the link between the hubs and the tire element, ensuring a secure and rigid connection while allowing the tire to flex during operation. These fasteners are typically made from high-strength steel and are tightened to specific torque specifications to prevent loosening during rotation. Washers or lock nuts are often used in conjunction with the bolts to further enhance the stability of the connection, particularly in high-speed or high-vibration applications. The number and size of the connecting bolts are determined by the coupling’s torque capacity, with larger couplings or those intended for heavy-duty use featuring more or larger-diameter bolts to distribute the load evenly across the tire element.

Protective covers are optional but common components in tire shaft coupling designs, serving to shield the tire element and connecting bolts from external contaminants such as dust, dirt, moisture, and debris. These covers also help to prevent accidental contact with the rotating components, enhancing operational safety. Typically made from sheet metal, plastic, or rubber, the covers are designed to be easily removable to facilitate inspection and maintenance. In some applications, the covers may also be equipped with seals to further improve protection against contamination, extending the service life of the tire element and other components.

The operating principle of a tire shaft coupling revolves around the elastic deformation and recovery of the tire element, which enables torque transmission while accommodating misalignments and absorbing shocks and vibrations. When the driver shaft rotates, it imparts rotational motion to the driver hub. This motion is transferred to the tire element via the connecting bolts, causing the tire to deform elastically as it transmits the torque to the driven hub. The elastic nature of the tire element allows it to flex in multiple directions, enabling the coupling to accommodate three types of shaft misalignment: angular misalignment (where the shafts intersect at an angle), parallel misalignment (where the shafts are parallel but offset from each other), and axial misalignment (where the shafts move along their longitudinal axis). As the tire element flexes to compensate for these misalignments, it minimizes the transfer of bending stresses and shear forces to the shafts and connected bearings, protecting these critical components from premature failure.

A key aspect of the tire shaft coupling’s operating principle is its exceptional vibration damping capability. Rotating machinery such as motors, pumps, and compressors generate vibrations due to imbalances, torque fluctuations, or operational irregularities. These vibrations, if unmitigated, can cause excessive noise, accelerate component wear, and even lead to structural damage in the mechanical system. The elastomeric tire element acts as a natural vibration damper: as vibrations are transmitted to the tire, its elastic deformation absorbs the vibrational energy, converting it into heat (which is then dissipated into the surrounding environment) rather than transferring it to the driven shaft and machinery. This damping effect is particularly pronounced in couplings with softer tire elements, though the stiffness of the tire must be carefully matched to the application’s torque requirements to avoid excessive deflection or loss of torque transmission efficiency.

Shock load absorption is another critical function of tire shaft couplings. In applications where the driven machinery may experience sudden load spikes—such as in mining equipment, crushers, or material handling systems—the tire element acts as a buffer, absorbing the impact of the shock load. By deforming elastically under the sudden increase in torque, the tire element distributes the load evenly across its structure, preventing concentrated stresses on the hubs, shafts, or connected equipment. This shock absorption capability not only protects the coupling itself but also extends the service life of the entire mechanical system by reducing the wear and tear caused by sudden load variations.

Tire shaft couplings offer a range of distinct advantages that make them a preferred choice for numerous industrial applications. One of the most significant advantages is their exceptional flexibility and misalignment compensation capability. Unlike rigid couplings, which require precise shaft alignment and can transmit harmful stresses when misaligned, tire shaft couplings can accommodate relatively large levels of angular, parallel, and axial misalignment. This flexibility eliminates the need for overly precise installation and alignment, reducing setup time and costs, and also compensates for misalignments that develop over time due to thermal expansion, bearing wear, or foundation settlement.

Superior vibration damping and noise reduction are additional key benefits. The elastomeric tire element effectively absorbs vibrational energy, minimizing the transfer of vibrations between the driver and driven machinery. This results in quieter operation, which is particularly valuable in applications where noise levels are tightly regulated, such as in residential areas, hospitals, food processing facilities, and pharmaceutical plants. Reduced vibration also translates to less wear on bearings, gears, and other rotating components, lowering maintenance costs and improving the overall reliability of the system.

The ability to absorb shock loads is another major advantage of tire shaft couplings. In harsh operating environments where sudden load spikes are common, the tire element acts as a protective buffer, preventing damage to the shafts, motors, and driven equipment. This makes tire shaft couplings ideal for heavy-duty applications such as construction machinery, mining equipment, and industrial crushers, where shock loads are inherent to the operational process.

Tire shaft couplings also offer excellent torque transmission efficiency. When properly sized and maintained, the tire element transmits torque uniformly across the coupling, minimizing power loss. The rigid connection between the hubs and the tire element (via the connecting bolts) ensures that there is no slippage during torque transmission, even under high-load conditions. This efficiency is particularly important in energy-intensive applications, where even small losses in power transmission can lead to significant increases in operational costs.

Easy installation and maintenance are additional advantages of tire shaft couplings. Their simple structure and modular design make them easy to assemble and disassemble without the need for specialized tools or expertise. Replacing the tire element—one of the most commonly worn components—is a straightforward process that can be completed quickly, reducing maintenance downtime. Furthermore, the protective covers (when equipped) provide easy access to the internal components for inspection and maintenance, simplifying the upkeep process.

Versatility and adaptability are also notable benefits of tire shaft couplings. They are available in a wide range of sizes, torque capacities, and tire element materials, allowing them to be tailored to suit diverse application requirements. Whether it is a lightweight coupling for a small electric motor or a heavy-duty coupling for a large industrial turbine, manufacturers can customize the design to meet specific torque, misalignment, and environmental constraints. This versatility makes tire shaft couplings suitable for use in a broad spectrum of industries and applications.

Due to their unique combination of advantages, tire shaft couplings find application in a diverse range of industrial, commercial, and automotive sectors. One of the most common applications is in the automotive industry, where they are used in the drivetrains of commercial vehicles such as trucks, buses, and trailers. In these vehicles, tire shaft couplings connect the transmission to the drive axle, absorbing torque fluctuations generated by the engine, reducing vibration, and accommodating minor misalignments between the transmission and axle shafts. This improves ride comfort and protects drivetrain components from damage, ensuring reliable operation even under heavy loads.

The manufacturing industry is another major user of tire shaft couplings, where they are employed in a wide range of machinery, including conveyors, mixers, agitators, extruders, and machine tools. Conveyors, which are used to transport materials in factories and warehouses, often experience sudden load variations and minor shaft misalignments due to the weight of the materials and the length of the conveyor system. Tire shaft couplings are ideal for this application, as they absorb shock loads and compensate for misalignments, ensuring smooth and reliable operation. Mixers and agitators, commonly used in the food, chemical, and pharmaceutical industries, generate significant vibrations during operation; tire shaft couplings dampen these vibrations, preventing damage to the mixer components and ensuring uniform mixing of materials.

In the renewable energy sector, tire shaft couplings are widely used in wind turbines and solar tracking systems. Wind turbines experience highly variable torque loads due to fluctuations in wind speed, and the rotating components (such as the rotor and generator) are prone to misalignment due to structural flexing. Tire shaft couplings in wind turbine drivetrains absorb these torque fluctuations, dampen vibrations, and accommodate misalignments, protecting the generator and other critical components from damage and ensuring efficient power generation. Similarly, in solar tracking systems, tire shaft couplings connect the drive motor to the tracking mechanism, allowing for smooth and precise movement while compensating for minor misalignments caused by thermal expansion and contraction.

The marine industry also relies on tire shaft couplings for various applications, including ship propulsion systems, marine pumps, and auxiliary machinery. Ship propulsion systems operate in harsh environments with high torque loads and potential misalignments between the engine and propeller shaft. Tire shaft couplings in these systems absorb shock loads from wave impacts, dampen vibrations, and accommodate misalignments, ensuring reliable power transmission and protecting the engine and propeller components. Marine pumps, which are used for ballasting, cooling, and fuel transfer, also benefit from the vibration damping and misalignment compensation capabilities of tire shaft couplings, extending their service life in corrosive marine environments.

Other notable applications of tire shaft couplings include mining equipment (such as crushers, grinders, and conveyors), where they withstand heavy shock loads and harsh environmental conditions; HVAC systems (such as fans, blowers, and chillers), where they reduce noise and vibration for improved indoor air quality and comfort; and small industrial appliances (such as compressors and pumps), where they connect the motor to the working components, absorbing vibrations and ensuring smooth operation.

To maximize the performance, reliability, and service life of tire shaft couplings, regular and proper maintenance is essential. Neglecting maintenance can lead to premature component failure, increased operational costs, and unplanned downtime. The following are key maintenance practices for tire shaft couplings:

Regular inspection is the foundation of effective tire shaft coupling maintenance. Inspections should be conducted at regular intervals (as recommended by the coupling manufacturer or based on operational hours) to check for signs of wear, damage, or degradation. During inspection, the coupling should be visually examined for cracks, tears, or hardening of the tire element—these are common signs of elastomeric material degradation due to age, temperature, or exposure to chemicals. The connecting bolts should also be checked for tightness, as loose bolts can cause excessive vibration and damage to the tire element and hubs. Additionally, the coupling should be checked for abnormal noise, vibration, or temperature rise during operation, which can indicate underlying issues such as a worn tire element, misalignment, or insufficient lubrication (for metal components).

Lubrication is a critical maintenance task for the metal components of tire shaft couplings, such as the hubs, connecting bolts, and shaft connections. Proper lubrication reduces friction between the hubs and shafts, minimizes wear, and prevents corrosion. The type of lubricant selected should be compatible with the coupling’s materials and operating conditions, including temperature, load, and environmental factors (such as exposure to moisture or chemicals). Common lubricants used for tire shaft couplings include lithium-based greases and synthetic oils. Lubrication should be performed at regular intervals, and old or contaminated lubricant should be completely drained and replaced to ensure optimal performance. It is important to note that the tire element itself does not require lubrication, as lubricants can degrade the elastomeric material and reduce its elasticity and service life.

Replacement of worn or damaged components is essential to maintain the coupling’s performance and prevent catastrophic failure. The tire element is the most vulnerable component, as it is subject to repeated elastic deformation and exposure to environmental factors. Worn, cracked, or hardened tire elements should be replaced immediately, as they can no longer effectively dampen vibrations or accommodate misalignments, which can lead to damage to the shafts and connected equipment. When replacing the tire element, it is important to use a component that is compatible with the coupling’s design and specifications to ensure proper fit and performance. The connecting bolts should also be inspected for wear or damage, and replaced if necessary. Loose or damaged fasteners should be tightened or replaced to ensure a secure connection between the hubs and tire element.

Proper shaft alignment should be checked and maintained regularly, even though tire shaft couplings can accommodate significant misalignments. Excessive or persistent misalignment beyond the coupling’s rated capacity can place additional stress on the tire element and hubs, leading to premature wear and failure. Shaft alignment can be measured using traditional tools such as a straightedge and feeler gauge, or more precise tools such as laser alignment systems, which provide accurate measurements and help minimize alignment errors. If misalignment is detected, corrective action should be taken immediately, such as adjusting the position of the motor or driven machinery, replacing worn bearings, or realigning the shaft supports.

Protection from external contaminants and harsh environments is another important maintenance practice. The coupling’s protective covers (if equipped) should be regularly inspected to ensure they are intact and functioning properly. If the coupling is operating in a particularly harsh environment (such as a dusty factory, wet marine setting, or corrosive chemical plant), additional protective measures may be required, such as installing additional protective shields, using corrosion-resistant coatings on the metal components, or selecting a tire element made from a material that is resistant to the specific environmental conditions. Regular cleaning of the coupling’s exterior can also help prevent the buildup of contaminants that may eventually damage the tire element or metal components.

In conclusion, tire shaft couplings are vital components in modern mechanical power transmission systems, offering a unique combination of flexibility, vibration damping, shock absorption, and torque transmission efficiency. Their design, which centers on the use of an elastomeric tire element, enables them to accommodate misalignments, reduce noise and vibration, and protect connected machinery from damaging stresses—features that make them indispensable in a wide range of applications across industries such as automotive, manufacturing, renewable energy, and marine.

Proper maintenance, including regular inspection, appropriate lubrication of metal components, timely replacement of worn tire elements and fasteners, maintenance of shaft alignment, and protection from contaminants, is crucial to ensuring the optimal performance and longevity of tire shaft couplings. By understanding the structural composition, operating principles, advantages, applications, and maintenance requirements of tire shaft couplings, engineers, maintenance professionals, and industrial operators can make informed decisions about their selection and use, ultimately improving the efficiency, reliability, and cost-effectiveness of their mechanical systems.

As industrial technology continues to advance, tire shaft coupling designs are likely to evolve to meet the growing demands of high-performance, high-efficiency machinery. Innovations in elastomeric materials (such as advanced rubber compounds with improved wear resistance and temperature tolerance), manufacturing processes (such as precision molding for more consistent tire element performance), and design optimization (such as computer-aided engineering for improved torque distribution) will further enhance the capabilities of tire shaft couplings. These advancements will enable tire shaft couplings to operate in even more extreme conditions, transmit higher levels of torque, and achieve longer service lives, ensuring that they remain a vital component in mechanical power transmission systems for years to come.

« Tire Shaft Couplings » Post Date: 2024/4/25 , https://www.rokeecoupling.net/tags/tire-shaft-couplings.html