Rokee is a well-known high-quality supplier of Tooth Gear Couplings and technical services in China, customize tooth gear couplings according to user drawings, alternatively, if the user provides tooth gear couplings parameters, we can select the model and design drawings for you, support wholesale and export.

In the complex landscape of mechanical power transmission, the demand for reliable, high-torque coupling solutions has driven the development of various mechanical components. Among these, the tooth gear coupling stands out as a critical element, designed to connect two rotating shafts and transmit torque while accommodating inherent misalignments. Unlike flexible couplings that rely on elastic elements, tooth gear couplings leverage meshing gear teeth to achieve power transfer, offering exceptional strength and durability in harsh operating environments. From heavy industrial machinery to marine propulsion systems, these couplings play an indispensable role in ensuring the smooth and efficient operation of equipment that demands high torque output and resistance to extreme conditions. This article provides a comprehensive exploration of tooth gear couplings, covering their fundamental design principles, structural components, working mechanisms, material selection criteria, diverse applications, maintenance protocols, and emerging trends, shedding light on why they remain a preferred choice for high-performance power transmission systems.

At its core, a tooth gear coupling is a type of rigid-flexible coupling that uses two sets of mating gear teeth—one attached to each shaft—to transmit rotational power. The defining characteristic of this coupling is its ability to accommodate three types of misalignment: angular misalignment (the angle between the two shafts), parallel misalignment (lateral offset between shaft axes), and axial displacement (linear movement along the shaft axis). This versatility stems from the design of the gear teeth, which are typically cut at an angle (helical) or straight (spur), allowing for relative movement between the coupled shafts without compromising torque transmission. Unlike rigid couplings that require precise shaft alignment and cannot tolerate any misalignment, tooth gear couplings provide a balance between rigidity and flexibility, making them suitable for applications where shaft misalignment is inevitable due to installation tolerances, thermal expansion, or structural deflection.

The historical evolution of tooth gear couplings is closely tied to the advancement of gear technology and the growing demand for high-torque power transmission in industrial applications. Early iterations of gear couplings date back to the late 19th century, when the industrial revolution drove the need for more efficient ways to connect rotating machinery. Initially, these couplings featured simple spur gear designs, which offered limited misalignment capacity. However, as manufacturing techniques improved—particularly the development of precision gear cutting and heat treatment processes—engineers were able to design more sophisticated tooth profiles, such as helical and curved teeth, which enhanced the coupling’s ability to handle misalignment and reduce vibration. Over the decades, tooth gear couplings have evolved to meet the increasing demands of modern industry, with designs optimized for higher torque densities, faster rotational speeds, and longer service lives.

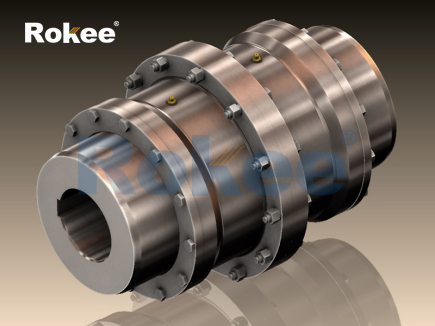

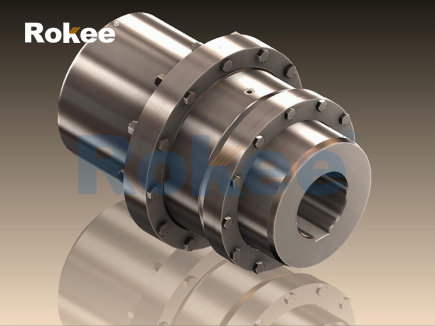

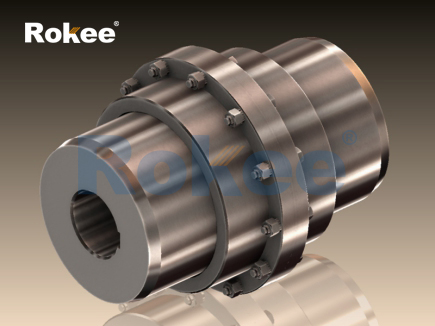

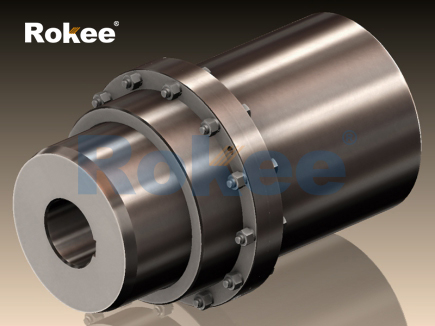

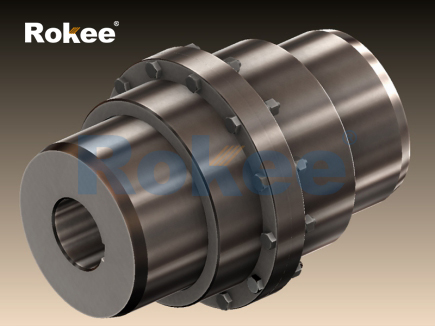

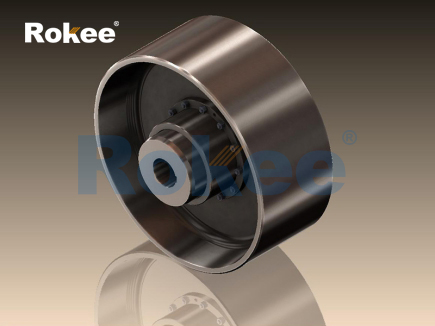

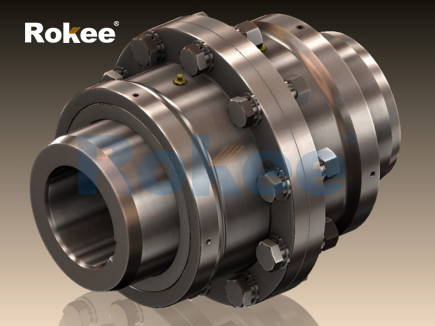

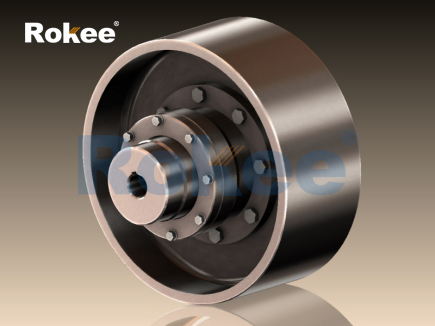

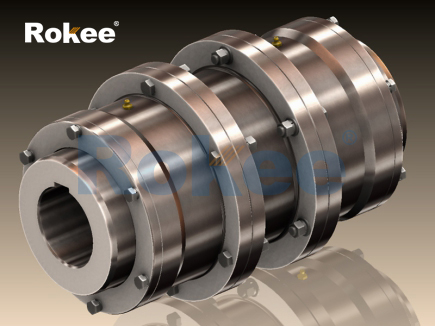

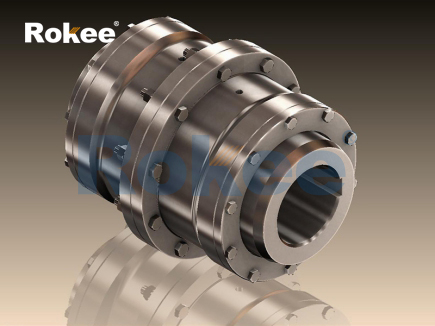

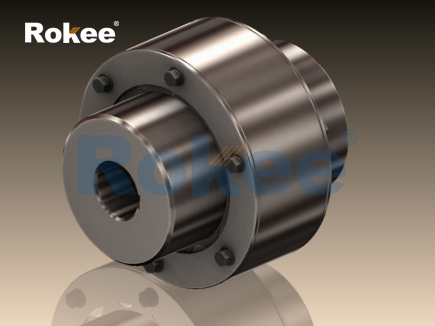

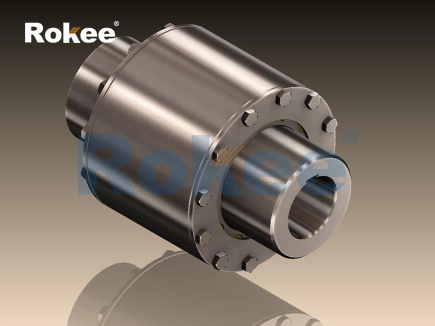

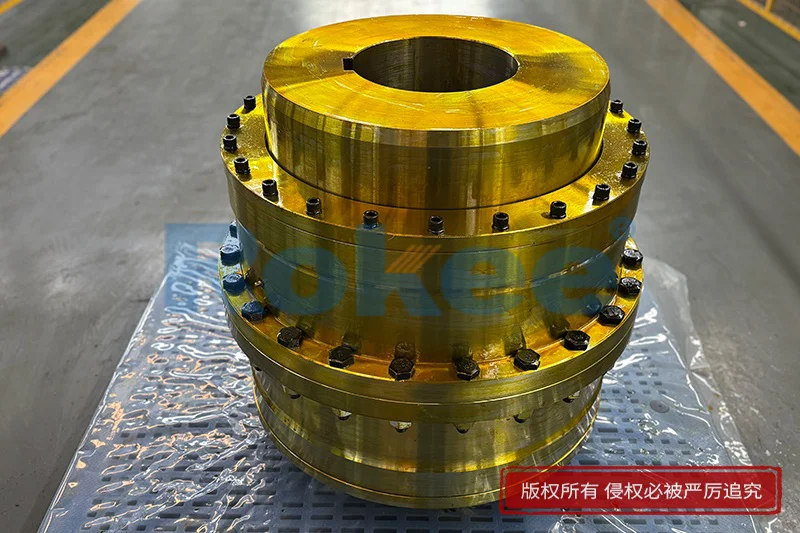

The structural composition of a tooth gear coupling is relatively intricate, with each component playing a vital role in ensuring reliable performance. The primary components include two gear hubs (also known as coupling halves), an outer sleeve (or cover), and a lubrication system. Each gear hub is attached to one of the shafts being coupled, typically via keyways, splines, or interference fits. The gear teeth are machined on the outer circumference of the hubs, and these teeth mesh with corresponding internal teeth machined on the inner surface of the outer sleeve. In some designs, the outer sleeve may be split into two halves, secured by bolts, to facilitate easy installation and maintenance. Additionally, many tooth gear couplings incorporate seals or gaskets to prevent the leakage of lubricant and protect the gear teeth from contamination by dust, debris, and moisture.

The gear teeth themselves are the most critical component of the coupling, as their design directly impacts torque capacity, misalignment tolerance, and overall durability. The two most common tooth profiles used in tooth gear couplings are spur teeth and helical teeth. Spur gear couplings feature straight teeth that are parallel to the shaft axis. They are simple to manufacture and cost-effective, making them suitable for low to moderate torque applications with minimal misalignment. However, spur teeth tend to generate higher levels of vibration and noise during operation, and their misalignment capacity is limited compared to helical designs. Helical gear couplings, on the other hand, have teeth that are cut at an angle to the shaft axis. This angled design allows for gradual meshing of the teeth, reducing vibration and noise while increasing the contact area between the teeth. As a result, helical tooth gear couplings can transmit higher torques, accommodate greater misalignments, and operate more smoothly than their spur gear counterparts. Some advanced designs also feature curved (or circular arc) teeth, which further enhance load distribution and misalignment capacity, making them ideal for extreme high-torque applications.

Lubrication is another critical aspect of tooth gear coupling design, as the meshing gear teeth are subject to high levels of friction and wear during operation. Proper lubrication reduces friction between the teeth, dissipates heat, and prevents corrosion, significantly extending the coupling’s service life. Most tooth gear couplings are lubricated with grease or oil, depending on the operating conditions. Grease is typically used for low to moderate speed applications, as it provides good sealing properties and requires less frequent reapplication. Oil lubrication is preferred for high-speed or high-temperature applications, as it offers better heat dissipation and can be circulated through a cooling system to maintain optimal operating temperatures. Many couplings also feature lubrication fittings (such as grease nipples) that allow for easy re-lubrication without disassembling the coupling.

Material selection is a key consideration in the design of tooth gear couplings, as the materials must withstand high torques, heavy loads, and harsh environmental conditions. The most commonly used materials for the gear hubs and outer sleeves include alloy steels, carbon steels, and stainless steels. Alloy steels—such as 4140, 4340, and 8620—are widely preferred due to their high strength, toughness, and wear resistance. These steels are often heat-treated (through processes such as quenching and tempering) to further enhance their mechanical properties, making them suitable for high-torque applications. Carbon steels are used in less demanding applications, as they are cost-effective but offer lower strength and wear resistance compared to alloy steels. Stainless steels are employed in applications where corrosion resistance is critical, such as marine environments, food processing facilities, or chemical plants. In some cases, the gear teeth may be surface-hardened (using processes such as carburizing, nitriding, or induction hardening) to improve their wear resistance while maintaining the toughness of the core material.

The working principle of a tooth gear coupling revolves around the meshing of the gear teeth on the hubs and the outer sleeve. When the driving shaft rotates, it imparts rotational motion to the attached gear hub. The teeth on this hub mesh with the internal teeth on the outer sleeve, causing the sleeve to rotate. The outer sleeve then transfers this rotational motion to the second gear hub, which is connected to the driven shaft. The key to the coupling’s ability to accommodate misalignment lies in the design of the gear teeth. For angular misalignment, the angled teeth (in helical or curved designs) allow the hubs to tilt relative to each other while maintaining meshing contact. For parallel misalignment, the clearance between the teeth and the flexibility of the coupling components enable the hubs to move laterally without binding. Axial displacement is accommodated by the sliding of the gear teeth along their length, as the hubs move towards or away from each other. Throughout this process, the lubricant ensures that the meshing teeth operate smoothly, minimizing friction and wear.

Tooth gear couplings are widely used across a diverse range of industries, thanks to their high torque capacity, misalignment tolerance, and durability. One of the primary applications is in heavy industrial machinery, such as steel mills, mining equipment, and power generation plants. In steel mills, for example, tooth gear couplings are used to connect the motors to rolling mills, which require extremely high torque to shape steel into various forms. The couplings must accommodate the misalignment caused by the heavy loads and thermal expansion of the equipment during operation. In mining operations, tooth gear couplings are used in crushers, conveyors, and pumps, where they transmit power in harsh, dusty environments and must withstand frequent shock loads. In power generation plants, they are used to connect turbines to generators, ensuring efficient power transmission even with slight misalignments between the shafts.

The marine industry is another major user of tooth gear couplings, where they are employed in propulsion systems to connect the engine to the propeller shaft. Marine propulsion systems demand high torque transmission and must accommodate misalignments caused by the movement of the ship’s hull and thermal expansion of the engine. Tooth gear couplings are ideal for this application due to their robust construction and resistance to corrosion in saltwater environments. Additionally, they are used in auxiliary marine equipment such as pumps, compressors, and winches.

In the automotive industry, tooth gear couplings are used in heavy-duty vehicles such as trucks, buses, and off-road vehicles. They are typically employed in the drive train to connect the transmission to the differential, where high torque transmission is required. Unlike universal joint shafts, which are commonly used in lighter vehicles, tooth gear couplings offer greater torque capacity and durability, making them suitable for heavy-duty applications. They are also used in automotive testing equipment, such as dynamometers, where precise torque transmission is essential.

Other applications of tooth gear couplings include industrial fans and blowers, where they connect the motor to the fan impeller and must accommodate the misalignment caused by the weight of the impeller and thermal expansion. They are also used in plastic extrusion machinery, where high torque is required to melt and shape plastic materials, and in paper mills, where they are used in the rolling and processing of paper. In each of these applications, the tooth gear coupling’s ability to transmit high torque while accommodating misalignment ensures the reliable and efficient operation of the equipment.

Proper maintenance is essential to ensure the longevity and reliable performance of tooth gear couplings. Neglecting maintenance can lead to premature failure, which can result in costly downtime, equipment damage, and safety hazards. The key maintenance practices for tooth gear couplings include regular inspection, lubrication, and replacement of worn components.

Regular inspection is critical to identify potential issues before they escalate into major problems. Inspections should include checking for signs of wear on the gear teeth (such as pitting, scuffing, or chipping), damage to the seals or gaskets, and loose fasteners. Vibration analysis can also be used to detect abnormal operating conditions, such as misalignment or worn bearings, which can affect the coupling’s performance. In addition, the coupling should be inspected for signs of corrosion, particularly in harsh environments such as marine or chemical plants.

Lubrication maintenance involves ensuring that the coupling is properly lubricated at all times. The frequency of lubrication depends on the operating conditions, such as speed, torque, and temperature. It is important to use the correct type of lubricant specified by the manufacturer, as using the wrong lubricant can lead to increased friction and wear. The lubricant level should be checked regularly, and the coupling should be re-lubricated whenever the lubricant becomes contaminated or degraded. Seals and gaskets should also be inspected during lubrication to ensure that they are functioning properly and preventing lubricant leakage.

Replacement of worn components is necessary when inspection reveals significant damage or wear. Worn gear teeth, damaged seals, and loose fasteners should be replaced promptly to prevent further damage to the coupling and the connected equipment. In some cases, the entire coupling may need to be replaced if the damage is severe. It is important to follow the manufacturer’s guidelines for component replacement to ensure that the new components are compatible with the coupling and meet the required performance specifications.

Looking ahead, the future of tooth gear couplings is shaped by the ongoing advancements in materials science, manufacturing technology, and the growing demand for more efficient and sustainable power transmission systems. One of the key trends is the development of lightweight, high-strength materials that reduce the weight of the coupling while maintaining or increasing its torque capacity. For example, the use of composite materials or advanced alloys is being explored to create couplings that are lighter and more corrosion-resistant than traditional steel couplings. This is particularly important in applications such as aerospace and electric vehicles, where weight reduction is critical for improving energy efficiency.

Another emerging trend is the integration of smart technology into tooth gear couplings. Smart couplings equipped with sensors can monitor operating conditions such as temperature, vibration, and torque in real time, providing valuable data to operators. This data can be used to predict potential failures, optimize maintenance schedules, and improve the overall efficiency of the power transmission system. For example, sensors can detect abnormal vibration patterns that indicate misalignment or worn gear teeth, allowing operators to address the issue before it leads to coupling failure.

Advancements in manufacturing technology are also driving improvements in tooth gear coupling design and performance. Precision machining techniques such as CNC (Computer Numerical Control) milling and grinding allow for the production of gear teeth with tighter tolerances, improving the meshing accuracy and reducing vibration. Additive manufacturing (3D printing) is also being explored as a way to produce complex coupling components with customized designs, enabling engineers to optimize the coupling for specific applications. Additionally, advanced heat treatment processes are being used to enhance the mechanical properties of the materials, further improving the coupling’s strength and wear resistance.

In conclusion, the tooth gear coupling is a robust and versatile component that plays a critical role in high-torque power transmission systems across a wide range of industries. Its ability to transmit high torque while accommodating misalignment, combined with its durability and reliability, makes it an indispensable part of modern mechanical equipment. From heavy industrial machinery to marine propulsion systems, tooth gear couplings ensure the smooth and efficient operation of equipment that demands high performance in harsh operating conditions. Proper maintenance practices, including regular inspection, lubrication, and component replacement, are essential to maximize the coupling’s service life and prevent costly downtime. As technology continues to advance, the future of tooth gear couplings looks promising, with innovations in materials, manufacturing, and smart technology set to further enhance their performance and efficiency. Whether in traditional industrial applications or emerging sectors such as electric vehicles and renewable energy, the tooth gear coupling will remain a key component in power transmission systems for years to come.

« Tooth Gear Couplings » Post Date: 2024/4/25 , https://www.rokeecoupling.net/tags/tooth-gear-couplings.html