-

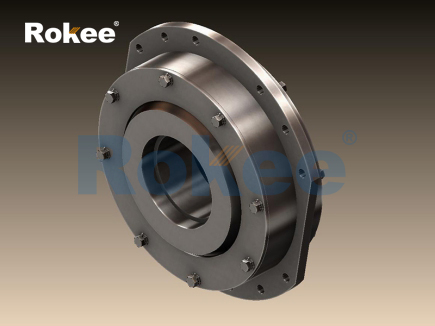

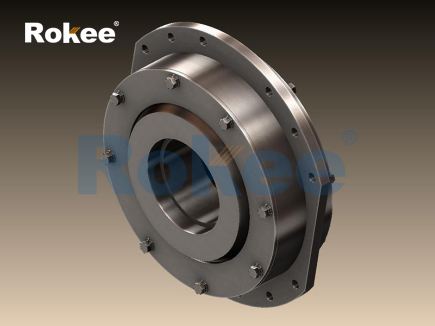

WZL Drum Coupling

WZL Drum Coupling is a spherical hinged coupling. It has a connecting flange with an inner spherical surface, a spherical semi-coupling sleeve with an outer spherical surface, a special transmission key, an inner and outer limit cover, etc. The internal control generally adopts the splined sleeve design, which transmits torque through a specially designed key bar and can withstand large torque and radial load. The maximum angular displacement compensation can reach 3°, with a life indicator and safe and reliable structure.View More -

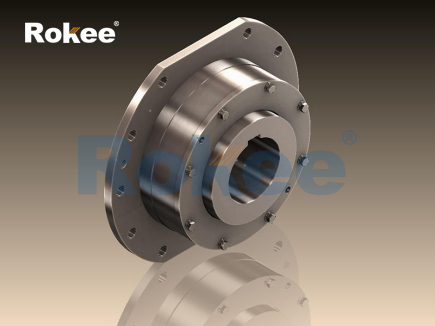

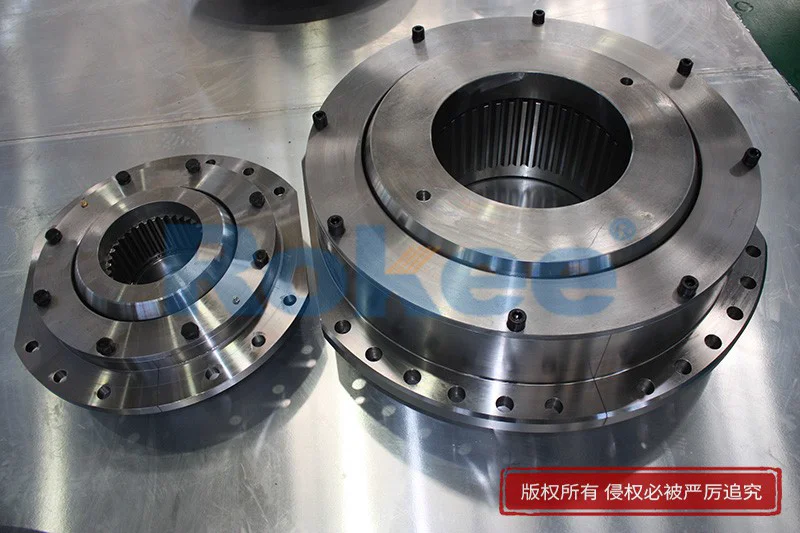

DC Drum Coupling

DC Drum Coupling is designed with drum teeth, which is used for connecting the reducer of crane transmission system with the drum. It can bear radial load and transfer large torque, but cannot transfer axial load.View More -

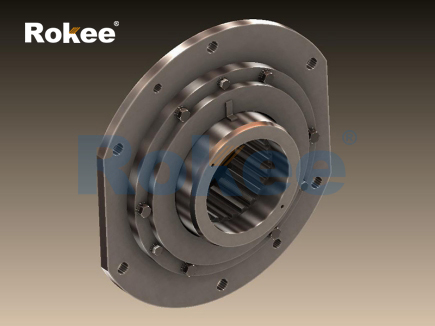

WJ Drum Coupling

WJ Drum Coupling is a spherical roller coupling, which is composed of jacket with connecting flange, spherical roller, semi-coupling, inner and outer cover plate and sealing system, capable of transmitting large torque and bearing radial load.View More -

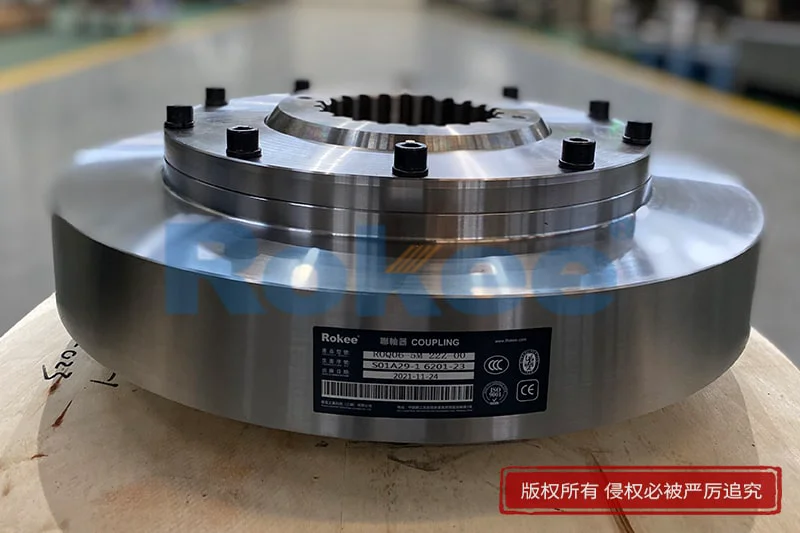

WJA Drum Coupling

WJA Drum Coupling is a spherical roller coupling, which is composed of jacket with connecting flange, spherical roller, semi-coupling, inner and outer cover plate and sealing system, capable of transmitting large torque and bearing radial load. The connection between the coupling and the output shaft of the reducer adopts an involute spline pair design.View More -

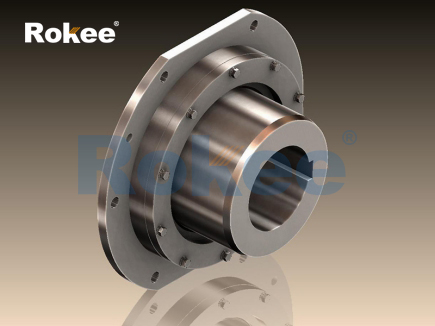

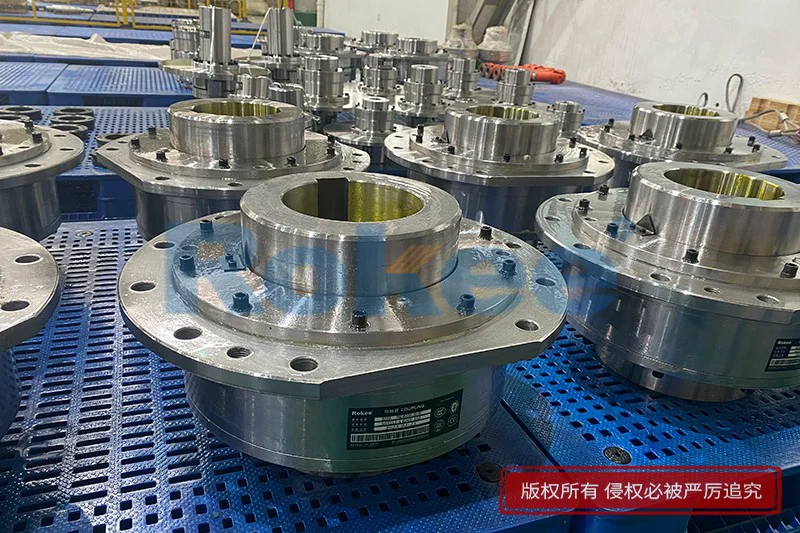

RWC Drum Coupling

The ball and drum gear drum coupling is a drum coupling developed by Rokee with a more reliable structure, higher compensation ability and higher safety factor. The outer sleeve adopts a spherical drum tooth design, which has low requirements for shafting installation accuracy, large transmission torque, strong overload capacity and can withstand great radial load. The connection size is the same as that of DC series, but the bearing capacity is increased by more than 30%. The innovative spherical sealing technology makes this type of product maintain excellent lubrication and greatly improve its service life.View More

Drum coupling is a specialized transmission device designed for lifting machinery, hoisting equipment, and other devices that require the transmission of rotational motion to the drum. This type of coupling plays a crucial role in industrial production, especially in situations where precise control of drum rotation and the ability to withstand large torques are required.

Unlike ordinary couplings, barrel couplings have special design features: they can withstand large radial loads, compensate for axial displacement, and have excellent impact resistance. This makes it an indispensable key component in heavy machinery such as cranes, port machinery, and mining equipment.

The drum coupling usually consists of the following core parts:

- Internal gear ring: a precision machined gear structure responsible for transmitting torque

- External gear sleeve: meshes with the internal gear ring, allowing for a certain degree of axial displacement

- Flange connection: used for connecting with motors or reducers

- Sealing system: prevents lubricant leakage and contamination from entering

- Buffer components: Some models are equipped with rubber or polyurethane buffer blocks to absorb impacts

This structural design enables the drum coupling to compensate for various shaft deviations, including radial deviation, angular deviation, and axial deviation, while transmitting high torque.

According to different application requirements, various types of barrel couplings have been developed:

- Gear type drum coupling: the most common type that transmits power through the meshing of internal and external gears

- Drum shaped gear coupling: The gear shape is drum shaped, allowing for greater angular deviation

- Elastic drum coupling: equipped with elastic elements, can better absorb impact and vibration

- Universal joint type drum coupling: suitable for situations requiring large angle deviation compensation

- Hydraulic drum coupling: transmits power through hydraulic principles to achieve stepless speed regulation

Performance advantages of barrel coupling

- High torque transmission capability: designed to withstand the large torque required by heavy machinery

- Excellent deviation compensation capability: capable of compensating for axial, radial, and angular deviations

- Long service life: Using high-quality materials and precision machining to ensure long-term reliable operation

- Easy to maintain: Most designs are maintenance free or only require regular lubrication

- Safe and reliable: overload protection design to prevent equipment damage

Drum couplings are widely used in various industrial fields:

- Lifting machinery: bridge crane, gantry crane, tower crane, etc

- Port equipment: container cranes, unloaders, loaders

- Mining machinery: mine hoist, conveying equipment

- Metallurgical industry: continuous casting machines, steel rolling equipment

- Wind power generation: yaw system and pitch system

- Construction machinery: concrete pump trucks, drilling equipment

The correct selection and installation of barrel couplings are crucial for equipment performance:

- Torque calculation: Calculate the required torque to be transmitted based on the load

- Speed matching: Consider the operating speed range

- Deviation assessment: estimate the possible deviation of the shaft system

- Environmental factors: Consider environmental conditions such as temperature, humidity, corrosiveness, etc

- Installation accuracy: Ensure the axis alignment accuracy during installation

- Lubrication requirements: Choose appropriate lubrication methods and lubricants

To ensure the long-term stable operation of the barrel coupling, the following maintenance work needs to be carried out regularly:

- Regular inspection: check for wear, sealing condition, and lubrication condition

- Lubrication management: Perform lubrication maintenance according to the manufacturer's requirements

- Vibration monitoring: Predicting potential faults through vibration analysis

- Temperature monitoring: Abnormal temperature rise is often a precursor to malfunction

- Regular alignment inspection: prevent early damage caused by increased shaft deviation

Common faults include tooth wear, lubrication failure, seal damage, etc. Timely detection and handling of these faults can extend the service life of the coupling.

As a key component in modern industrial transmission systems, the performance of drum couplings directly affects the operational efficiency and reliability of the entire equipment. With the improvement of industrial automation and intelligence, the requirements for barrel couplings will also become increasingly high, promoting continuous innovation and development in this field.

Cases of Drum Couplings

DC035 Crown Gear Drum Coupling

DC035 Crown Gear Drum Coupling Internal Spline Drum Coupling

Internal Spline Drum Coupling ROQ Drum Coupling

ROQ Drum Coupling Ball Joint Drum Coupling For Crane

Ball Joint Drum Coupling For Crane WZL Internal Spline Drum Coupling

WZL Internal Spline Drum Coupling

Related Articles

- 2024-05-31Barrel Coupling For Pump

- 2024-05-31Barrel Coupling For Bridge Crane

- 2024-05-31Barrel Coupling For Shop Traveller

- 2024-05-31Barrel Coupling For Water Pump

- 2024-05-31Barrel Coupling For Traveling Crane

- 2024-05-31Barrel Coupling For Overhead Traveling Crane

- 2024-05-31Barrel Coupling For Crane

- 2024-05-31Ball Dumpling Barrel Coupling

- 2024-05-31Ball Hinge Barrel Coupling

- 2024-05-31Spherical Roller Barrel Coupling

- 2024-05-31Internal Spline Barrel Coupling

- 2024-05-31Drum Gear Barrel Coupling

- 2024-05-31Drum Coupling For Pump

- 2024-05-31Drum Coupling For Bridge Crane

- 2024-05-31Drum Coupling For Shop Traveller

- 2024-05-31Drum Coupling For Water Pump

- 2024-05-31Drum Coupling For Traveling Crane

- 2024-05-31Drum Coupling For Overhead Traveling Crane

- 2024-05-31Drum Coupling For Crane

- 2024-05-31Ball Dumpling Drum Coupling